This may be a bit more work than you would like but it works well, it helps to have a surface grinder. It can be ground freehand with patience.

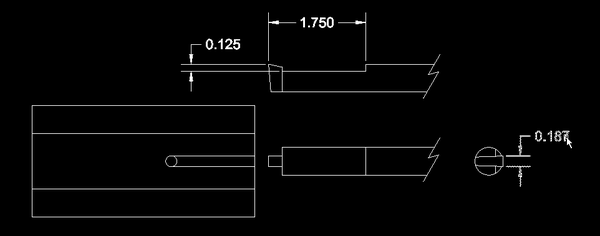

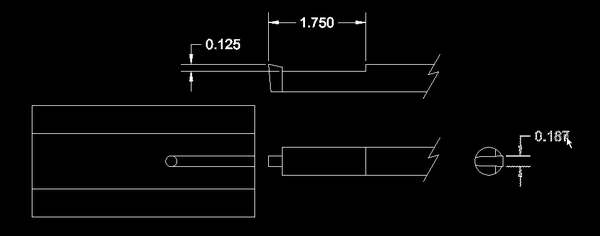

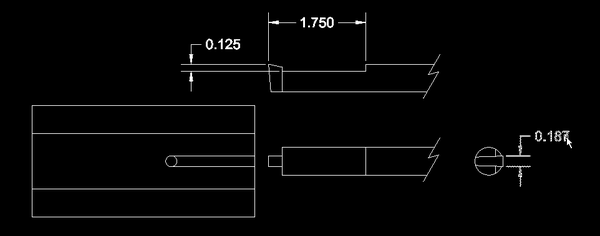

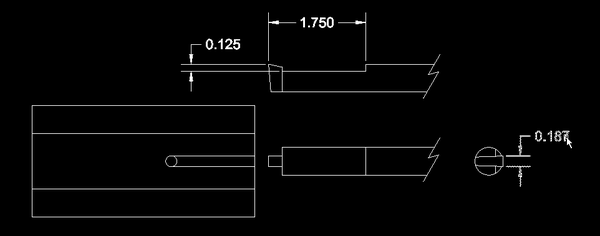

Buy a 1/2-5/8" HSS reamer blank.

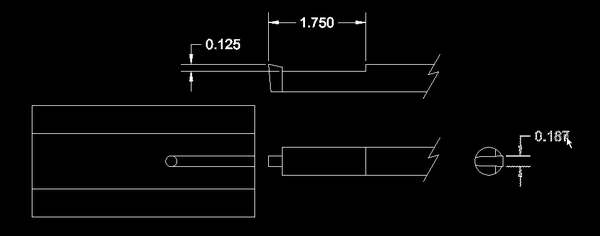

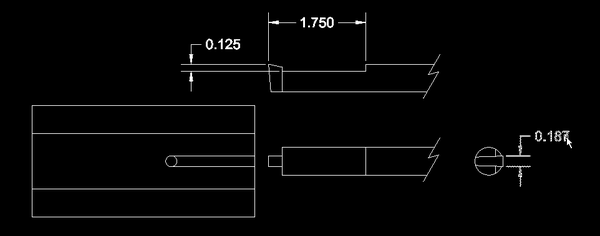

Grind it similar to the attached drawing. Only grind as much of the blank away as needed to clear the work in order to leave the tool a rigid as possible. Add cost of tool to invoice.

Mount in tool post on center. If you have a QC tool block with a V-Groove all the better.

Lock spindle, I put the lathe in back gear and direct drive at the same time, put a block of material on the ways and use a jack against one of the jaws to remove any backlash. (Or find a way that works on your machine) DO NOT TURN SPINDLE ON

Drill a hole through the part where the keyway will end so that the chip breaks off, alternatively, if a hole is not permissible turn a groove in the bore.

Run tool in by hand with the carriage using the cross slide to control the depth, set a carriage stop so that the tool stops at the center of the hole, (or groove). Advance cross slide and repeat as needed, this may take MANY passes. Use a cutting fluid and don't get greedy with the DOC. Depending on the size of the tool blank and rigidity of the machine of course.

This is Lathe as manual Shaper, cut keyway(s), put tool in toolbox most likely never to be used again.

Find tool several years later and wonder why you made it, this is optional but happens to me often, I have hundreds of tools and fixtures that I have no idea what I made them for.

A 1/2" blank is $12.20 from McMaster-Carr

http://www.mcmaster.com/#reamer-blanks/=vlv9yj