- Joined

- Aug 22, 2012

- Messages

- 4,260

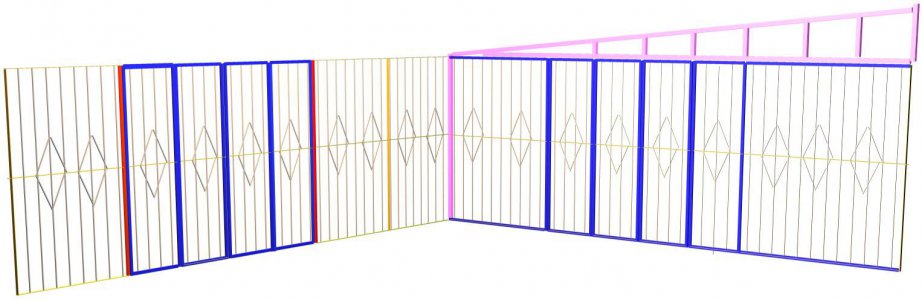

I will be welding up a bunch of steel frames and screens to screen my patio.

The design I have come up with is --

The outer frame is 35x5mm flat bar, the verticals are 10mm square.

The blue parts are bifold doors.

rather than cut the verticals in half with a possible miss alignment at the central cross piece I thought I would drill holes in it to pass the verticals through then tack each one in place top bottom and middle first and finish welding them fully in place once they are all tacked.

I'm not so worried about mild twist in the flatness of the frame as I think that will disappear once bolted in place.

What I am unsure about is the twist that may occur in that middle rail from the welding process.

Anyone any ideas?

The design I have come up with is --

The outer frame is 35x5mm flat bar, the verticals are 10mm square.

The blue parts are bifold doors.

rather than cut the verticals in half with a possible miss alignment at the central cross piece I thought I would drill holes in it to pass the verticals through then tack each one in place top bottom and middle first and finish welding them fully in place once they are all tacked.

I'm not so worried about mild twist in the flatness of the frame as I think that will disappear once bolted in place.

What I am unsure about is the twist that may occur in that middle rail from the welding process.

Anyone any ideas?

Last edited: