- Joined

- Apr 28, 2014

- Messages

- 3,594

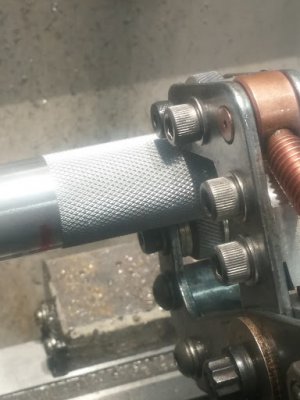

Here's my take on modding a Kant-Twist for a scissors style knurler.

Been messing with knurling Ø1" copper and brass tubes. Consistency with 'bump' knurlers has not been attainable, at least not with my skill level.

Bought an import 3-position fine-medium-course, bought some US made wheels and still not quite there. too much pressure.

I've come to the conclusion that knurling is 89% luck and requires proper alignment of the sun, moon and stars.

Anyway I thought I'd try making a clamp type scissors tool.

In hind sight I should have perhaps put my effort into making Hawkeye's Camjack Knurler.

The donor is an old #410 which it would appear spent it's life in a XEROX Tool Room. It was pretty loose and worn out.

My thought was to assemble it with solid blocks to beef up the arms.

So here's my Kant-Twist-XEROX-Strongback Knurler...

Been messing with knurling Ø1" copper and brass tubes. Consistency with 'bump' knurlers has not been attainable, at least not with my skill level.

Bought an import 3-position fine-medium-course, bought some US made wheels and still not quite there. too much pressure.

I've come to the conclusion that knurling is 89% luck and requires proper alignment of the sun, moon and stars.

Anyway I thought I'd try making a clamp type scissors tool.

In hind sight I should have perhaps put my effort into making Hawkeye's Camjack Knurler.

The donor is an old #410 which it would appear spent it's life in a XEROX Tool Room. It was pretty loose and worn out.

My thought was to assemble it with solid blocks to beef up the arms.

So here's my Kant-Twist-XEROX-Strongback Knurler...