Hi All

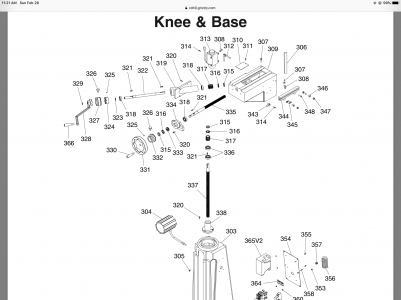

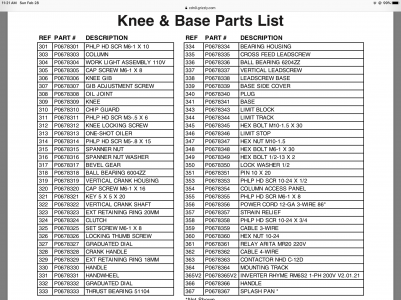

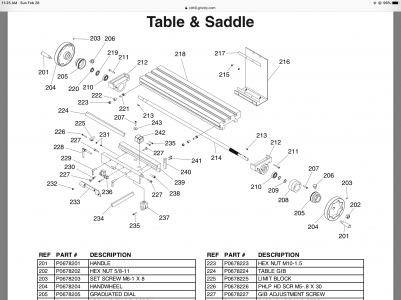

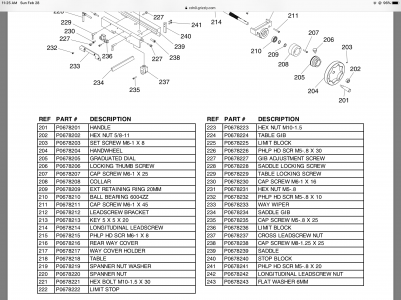

I've been on a house renovation project since September but now I am just getting to use my new Grizzly G0678 mill, which I frickin' love.

Anyways, I do have one annoying issue with it. Those big hand wheels keep tightening up on me.

So before the handle goes onto the axle the graduated dial goes on first, then the handle goes on, gets lined up with the keyway and then a set screw tightens it down into place. I discovered that about a 32'nd to a 16'th of an inch gap on either side of the graduated dial helps the wheel turn smoothly, and I mean super smooth. However, what keeps happening is this... When I turn the handle clockwise it runs smoothly but often when I turn it counterclockwise the handle tightens up the gaps on either side of the graduated dial, which makes turning much harder.

So, why is this happening? The wheel is not on threads on the axle and the set screw is tightened pretty good.

Any and all help is greatly appreciated.

I've been on a house renovation project since September but now I am just getting to use my new Grizzly G0678 mill, which I frickin' love.

Anyways, I do have one annoying issue with it. Those big hand wheels keep tightening up on me.

So before the handle goes onto the axle the graduated dial goes on first, then the handle goes on, gets lined up with the keyway and then a set screw tightens it down into place. I discovered that about a 32'nd to a 16'th of an inch gap on either side of the graduated dial helps the wheel turn smoothly, and I mean super smooth. However, what keeps happening is this... When I turn the handle clockwise it runs smoothly but often when I turn it counterclockwise the handle tightens up the gaps on either side of the graduated dial, which makes turning much harder.

So, why is this happening? The wheel is not on threads on the axle and the set screw is tightened pretty good.

Any and all help is greatly appreciated.