As in the title. I have a so called U3 "universal" tool cutter grinder (a Deckel D0 Chinese clone). Some months ago I bought what was then described as a CBN grinding wheel (no grit number etc). It was bought from some guy selling new-old soviet made things. Previously he was quite reliable. When the wheel came I noticed it had green bonding resin and marking in Russian letters KB. I assumed that KB stands for cubic boron in Russian. It also had markings 100x80 and letters AOC. I assumed that 80 would be grit size and 100 is diameter. There was also some handwriting on wrap paper that had wheel dimensions and "10c". That was first when I became a bit surprised, is cbn measured in carats too?

The wheel had wrong hole size so I didn't use it for few months. However, as of recently I need a tiny boring bar (for a 3mm hole) and I had some 4mm hss rounds on hand so I decided to try my "cbn" wheel. I made an adapter to mount it on my grinder and I noticed it cuts very slowly, but leaves a mirror-like finish as if it was extremely fine grit. When pressed slightly harder it generated quite a bit of heat and didn't cut better. When stopped it looks as it was glazed. I gave it a bit of aluminium oxide stick, but it made no difference.

So I'm now suspecting this is not a CBN, but hard bond diamond with fine grit. I'm considering de-glazing it with a very fine grit sharpening stone as I assume my aluminium oxide didn't work due to big grain size. Then I'll be trying it with a piece of carbide to see if it cuts. Would cbn cut carbide at all?

I'm starting this thread to ask if there is any way to tell cbn from diamond other than by performance. Do they look different under a microscope etc? Perhaps there is some characteristics of one and not the other I can test.

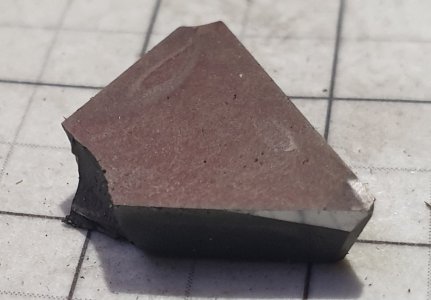

Attached is the wheel photo (with my adapter installed).

The wheel had wrong hole size so I didn't use it for few months. However, as of recently I need a tiny boring bar (for a 3mm hole) and I had some 4mm hss rounds on hand so I decided to try my "cbn" wheel. I made an adapter to mount it on my grinder and I noticed it cuts very slowly, but leaves a mirror-like finish as if it was extremely fine grit. When pressed slightly harder it generated quite a bit of heat and didn't cut better. When stopped it looks as it was glazed. I gave it a bit of aluminium oxide stick, but it made no difference.

So I'm now suspecting this is not a CBN, but hard bond diamond with fine grit. I'm considering de-glazing it with a very fine grit sharpening stone as I assume my aluminium oxide didn't work due to big grain size. Then I'll be trying it with a piece of carbide to see if it cuts. Would cbn cut carbide at all?

I'm starting this thread to ask if there is any way to tell cbn from diamond other than by performance. Do they look different under a microscope etc? Perhaps there is some characteristics of one and not the other I can test.

Attached is the wheel photo (with my adapter installed).