I watched the Joe.P YouTube video Threading on a manual lathe BEST TECHNIQUE EVER !!!!

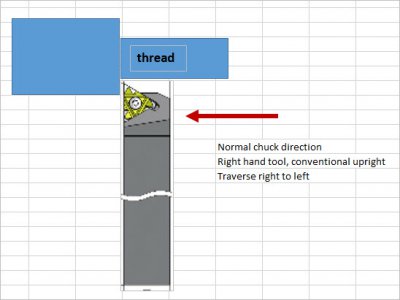

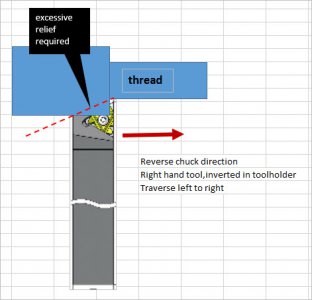

The gist of the demo is: He inverts a left hand threading tool holder, reverses the chuck rotation (thus reversing the lead screw direction) in order to traverse from left to right (headstock to tailstock direction). So now he begins in the relief groove, threads out safely past the end & repeats. This, as opposed to the 'conventional' direction of forward chuck rotation, traversing right to left with right hand tool & the pucker factor of disengaging thread or otherwise stopping the threading operation within the relief groove & not beyond.

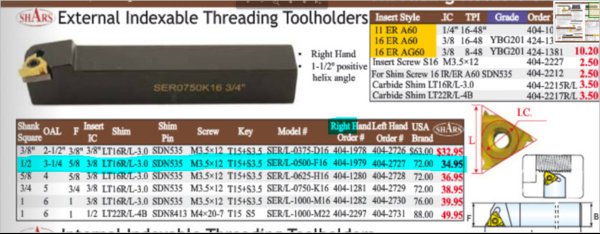

I don't do a ton of threading. Right now I have el-cheapo brazed carbide tipped threading tool of the offshore variety, external only. I've been a Right-To-Left, stop short & hand turn the last bit, conservative kinda guy but it still requires staying alert threading towards a shoulder. Now I have to do metric threads which means my lead screw must stay engaged throughout. Plus I have to do some internal threading & don't have tooling so I'm evaluating options. A popular style seems to be triangular flat inserts with 3 Vee shaped nibs. They come in all sizes, internal, external, different IC. Yes, more $ and yet another set of inserts to consider. From what I can tell a 'pro' line like Carmex appears to be the same standard being cloned by the likes of Shars for about half price & cheaper again on Ali. The partial form inserts can be found at the usual discount places I've had decent luck with regular cutting inserts.

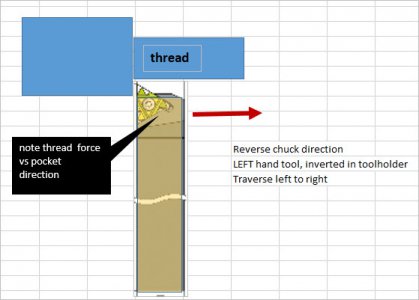

Back to the Joe.P topic. Can the triangular style inserts function in the same (inverted left to right) mode? It seems to me the only way it could work with a shoulder is an inverted left hand tool holder, but then the forces are pulling on the insert away from the pocket. Can these be operated like this? Hopefully pics illustrate what I mean.

The gist of the demo is: He inverts a left hand threading tool holder, reverses the chuck rotation (thus reversing the lead screw direction) in order to traverse from left to right (headstock to tailstock direction). So now he begins in the relief groove, threads out safely past the end & repeats. This, as opposed to the 'conventional' direction of forward chuck rotation, traversing right to left with right hand tool & the pucker factor of disengaging thread or otherwise stopping the threading operation within the relief groove & not beyond.

I don't do a ton of threading. Right now I have el-cheapo brazed carbide tipped threading tool of the offshore variety, external only. I've been a Right-To-Left, stop short & hand turn the last bit, conservative kinda guy but it still requires staying alert threading towards a shoulder. Now I have to do metric threads which means my lead screw must stay engaged throughout. Plus I have to do some internal threading & don't have tooling so I'm evaluating options. A popular style seems to be triangular flat inserts with 3 Vee shaped nibs. They come in all sizes, internal, external, different IC. Yes, more $ and yet another set of inserts to consider. From what I can tell a 'pro' line like Carmex appears to be the same standard being cloned by the likes of Shars for about half price & cheaper again on Ali. The partial form inserts can be found at the usual discount places I've had decent luck with regular cutting inserts.

Back to the Joe.P topic. Can the triangular style inserts function in the same (inverted left to right) mode? It seems to me the only way it could work with a shoulder is an inverted left hand tool holder, but then the forces are pulling on the insert away from the pocket. Can these be operated like this? Hopefully pics illustrate what I mean.