- Joined

- Apr 12, 2012

- Messages

- 579

I just finished adding this to my web site in hopes it would help a few. Since it seems posts are dropping out due to the change over / growing pains. This was cut and past and'll give someone something to do I hope.

It seems that very often people have a little trouble with inserts for cutting tools. Generally each manufacturer will go by either ANSI or ISO standards and sometimes reference both.

TCMT2.51 Insert clearance angle C=7° This can be changed depending on what your material needs**** add more later.

TCMT21.51 3rd position is tolerance class. M is pretty low. If you see anything else in this position (unlikely) except U or N it would be an improvement with no real effect.

TCMT21.51 Insert features.T, with hole, one countersink, and chip groove on one rake face. Pretty much can't change this and still get the larger screw to fit.

TCMT21.51 Size in qty of 1/8" 2 in this case because the inscribed circle of the 3/8" holders in our example is 1/4" can't change or the insert will be too big/small for the holders.

TCMT21.51 Thickness in qty of 1/16" x 1.5 or 3/32" changing by .5 +- probably would not make much difference except adjusting the height at the tool post.may be no decimal

TCMT21.51 Corner Radius in qty of 1/64" can (should) be changed. 1 = 1/64" which is pointy. changing to somthing rounder can offer an improvement in surface finish.

So that pretty much completes the information included with our example ANSI inserts. If you go to page 108-109 (or whichever has your actual insert) you'll see that it is conviently listed in both ANSI and ISO. TCMT110204 is the ISO # for TCMT21.51. Note that the decimal in size can be left out as is Kennametals want. Each different manufacturer adds to the end some more designations outside the ISO / ANSI standards to catalog specifics. Sorta like auto makers add lariat, rally etc

I have nothing to do with any mentioned brand I just gotta start somewhere!

refinements and more to come (I hope)

Edited to remove lines and adjust the highlighting.

Steve

It seems that very often people have a little trouble with inserts for cutting tools. Generally each manufacturer will go by either ANSI or ISO standards and sometimes reference both.

If you have name brand holders such as Kennametal, Sandvik, ISCAR, etc. It is really as simple as calling the manufacturer/distributer help desk with the identification of an insert that you are currently using (ie TCMT21505LF), material you want to cut, finish desired, and model # of the holder. They will make recommendations.

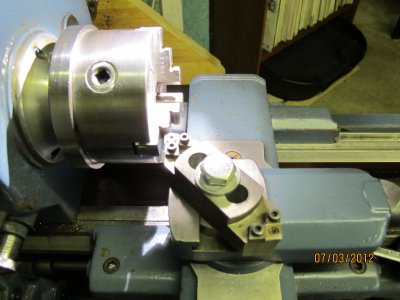

Many of us in the home hobby machining have bought into the 30$ chinese holder set from one of the many import places. I'm going to use that varity as an example but the principle will hold true even if you have something completly different ie CNMP431 Kennametal has a very nice catalog of turning inserts with the 1st several pages being pretty much everything most of us need to know about how the ID/Catalog #s work. You probably should open it and leave it in a window while you continue being bored by me.

So you bought the set and the seller said "uses TCMT21.51 inserts". That's ANSI description. You bought a 3/8 shank set and each holder came with an insert on it and no spares. Hmmm the inserts are like 5$ each and you aren't really happy with the way they cut and would like to change something such as the tip radius may give a better finish if larger etc. So we need to determine what changes we can make in # TCMT21.51 and still have it fit our holder (later edit changed the highlight color to make it more obvious)

TCMT21.51 1st position is the shape. This cannot change round peg triangular hole.

TCMT2.51 Insert clearance angle C=7° This can be changed depending on what your material needs**** add more later.

TCMT21.51 3rd position is tolerance class. M is pretty low. If you see anything else in this position (unlikely) except U or N it would be an improvement with no real effect.

TCMT21.51 Insert features.T, with hole, one countersink, and chip groove on one rake face. Pretty much can't change this and still get the larger screw to fit.

TCMT21.51 Size in qty of 1/8" 2 in this case because the inscribed circle of the 3/8" holders in our example is 1/4" can't change or the insert will be too big/small for the holders.

TCMT21.51 Thickness in qty of 1/16" x 1.5 or 3/32" changing by .5 +- probably would not make much difference except adjusting the height at the tool post.may be no decimal

TCMT21.51 Corner Radius in qty of 1/64" can (should) be changed. 1 = 1/64" which is pointy. changing to somthing rounder can offer an improvement in surface finish.

So that pretty much completes the information included with our example ANSI inserts. If you go to page 108-109 (or whichever has your actual insert) you'll see that it is conviently listed in both ANSI and ISO. TCMT110204 is the ISO # for TCMT21.51. Note that the decimal in size can be left out as is Kennametals want. Each different manufacturer adds to the end some more designations outside the ISO / ANSI standards to catalog specifics. Sorta like auto makers add lariat, rally etc

I have nothing to do with any mentioned brand I just gotta start somewhere!

refinements and more to come (I hope)

Edited to remove lines and adjust the highlighting.

Steve

Last edited: