- Joined

- Oct 16, 2017

- Messages

- 341

In a previous thread (Vertical Metal Cutting Bandsaw Recommendation) Dabbler asked me to post pics and I will give my first impressions.

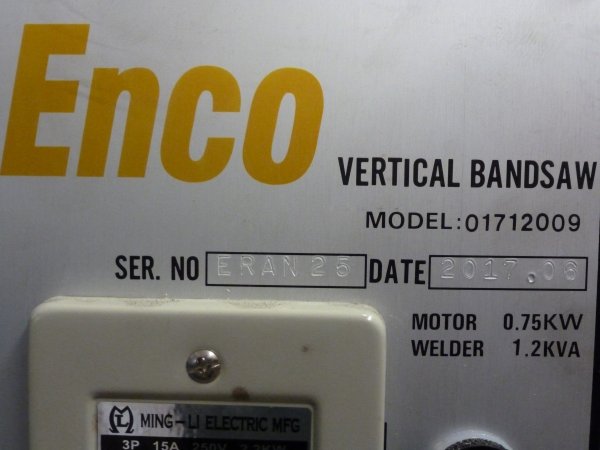

Disclaimer - I have never owned this type of machine so do not have a basis of comparison. I did do a lot of careful online research looking for what I thought to be the best saw in this size range. Did I nail it? Who knows. I can say though that of all the machines I own (PM935GT, PM1340GT, Wellsaw 58BW, Grizzly 1276, Ellis 9400) this machine is built to a much higher standard in terms of fit, finish and design. Everything on it is extremely well made and heavy duty. All adjustment points are high quality Allen head cap screws.

I purchased from MSC who were good to deal with and worked with my tight shipping window. The machine was fully crated in plywood and bolted to a heavy pallet base, shipped vertical, no damage. I picked it up from a local freight company and transported on my trailer horizontal with no issue.

According to the manual shipped with the machine CO is Taiwan -

The entire frame is 3/16" steel and doors are 3/32" steel. It runs whisper quite with no vibration. I am in the process of building a mobile base since I may need to move the machine for better access to my table saw.

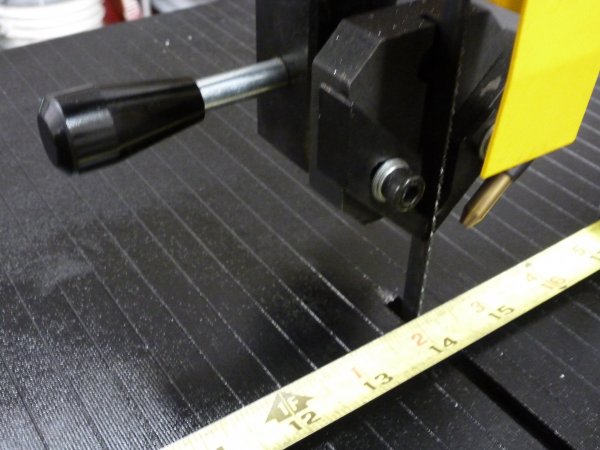

The table is cast iron (~45 lbs), limited tilt range x and y, 19-3/4" x 19-3/4" and 7/16" thick at the thinnest point (between the web), 39" from base to table top and mounted on a cast iron trunnion -

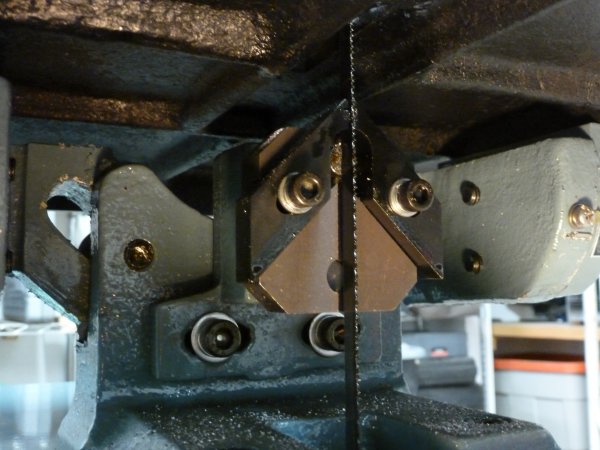

The blade guides appear universal and adjustment is straight forward -

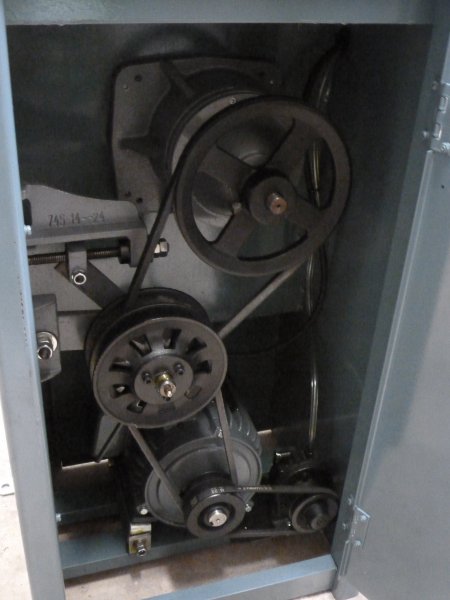

One of the main reasons for purchasing this machine for me was variable speed adjustment in a totally enclosed housing. The drive train appears solid and well built -

Blade speed is 80 - 300 ft/min -

The wheels are cast iron and the adjustable blade guide is a sold bar through guided by adjustable cast iron track. The blade guards are well placed and solid -

I have not used the blade shear/weld/grind feature -

The handy tension setting guide shows range 1/8" - 1" though the manual states maximum blade width 1/2".

Disclaimer - I have never owned this type of machine so do not have a basis of comparison. I did do a lot of careful online research looking for what I thought to be the best saw in this size range. Did I nail it? Who knows. I can say though that of all the machines I own (PM935GT, PM1340GT, Wellsaw 58BW, Grizzly 1276, Ellis 9400) this machine is built to a much higher standard in terms of fit, finish and design. Everything on it is extremely well made and heavy duty. All adjustment points are high quality Allen head cap screws.

I purchased from MSC who were good to deal with and worked with my tight shipping window. The machine was fully crated in plywood and bolted to a heavy pallet base, shipped vertical, no damage. I picked it up from a local freight company and transported on my trailer horizontal with no issue.

According to the manual shipped with the machine CO is Taiwan -

The entire frame is 3/16" steel and doors are 3/32" steel. It runs whisper quite with no vibration. I am in the process of building a mobile base since I may need to move the machine for better access to my table saw.

The table is cast iron (~45 lbs), limited tilt range x and y, 19-3/4" x 19-3/4" and 7/16" thick at the thinnest point (between the web), 39" from base to table top and mounted on a cast iron trunnion -

The blade guides appear universal and adjustment is straight forward -

One of the main reasons for purchasing this machine for me was variable speed adjustment in a totally enclosed housing. The drive train appears solid and well built -

Blade speed is 80 - 300 ft/min -

The wheels are cast iron and the adjustable blade guide is a sold bar through guided by adjustable cast iron track. The blade guards are well placed and solid -

I have not used the blade shear/weld/grind feature -

The handy tension setting guide shows range 1/8" - 1" though the manual states maximum blade width 1/2".

Last edited: