- Joined

- Feb 2, 2013

- Messages

- 3,957

I had a flash of inspiration last week after making due with improper measuring devises

i had a job that required sleeving a worn bearing retainer

i have DTI's but the worn area in the housing was deeper than a DTI would indicate.

so i made tangential drop indicator readings because i didn't have an indirect method of making the measurements

this is incorrect, but i had to get an idea of the depth of damage, so i could consider sleeve dimensions.

i got through the job, using a .001" DTI, but the experience made me think of designs using a drop indicator for indirect measurement.

Starrett has a few different indirect measurement options like the 670A

but i wanted to design my own that would mount in an AXA holder

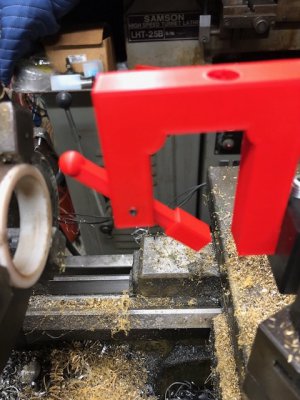

I designed and 3D printed a working prototype on Tinkercad.

I would like to share the inspired work with the peanut gallery

without further adieu, my abomination of indirect measurement in PLA

since i have a working prototype, i'll be copying the assembly in steel next!

thanks for reading!!!

i had a job that required sleeving a worn bearing retainer

i have DTI's but the worn area in the housing was deeper than a DTI would indicate.

so i made tangential drop indicator readings because i didn't have an indirect method of making the measurements

this is incorrect, but i had to get an idea of the depth of damage, so i could consider sleeve dimensions.

i got through the job, using a .001" DTI, but the experience made me think of designs using a drop indicator for indirect measurement.

Starrett has a few different indirect measurement options like the 670A

but i wanted to design my own that would mount in an AXA holder

I designed and 3D printed a working prototype on Tinkercad.

I would like to share the inspired work with the peanut gallery

without further adieu, my abomination of indirect measurement in PLA

since i have a working prototype, i'll be copying the assembly in steel next!

thanks for reading!!!