- Joined

- Aug 29, 2011

- Messages

- 28

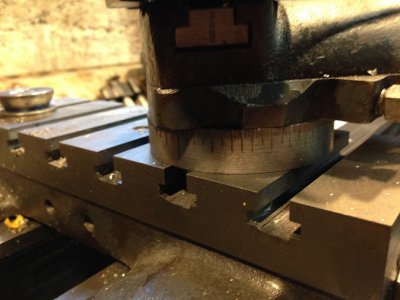

I just finished getting my "new to me" South Bend 9A under-drive lathe running and making chips and I'm making progress on refurbishing my South Bend 16" with the 12' bed. For the last 6 years, I've been using a A-C 12x36 model 101-07403 and a 6x18 model 101-07301. I've noticed during the last several years how both of the Atlas lathe lack a lot of rigidity. On 12L14, how deep of a cut will they take? It seems that the compound and cross slide ways have a lot of lay in them even with the gib screw tightened to the point they make the handles a bit hard to turn. Is there any way to take out the slack that allows movement under load or should I relegate them to light duty like brass, aluminum and plastics only? Since I've never turned a single piece of aluminum or plastic and only one piece of brass in the past 6 years, it seems a waste to let them sit there on the bench.

Should I look at making new gibs out of bra, use moglice to build up the ways to compensate for wear or maybe look for replacement parts that have less wear? Or just pass them on to someone who may be just getting started? I'm not expecting to turn them into Monarch 10EE class machines, just improve them a bit. After using the 9A, I'm not sure that either of them will get any future use in my shop. I've actually started looking for a SB 13" to slot between my 9" and 16" machines.

James

Should I look at making new gibs out of bra, use moglice to build up the ways to compensate for wear or maybe look for replacement parts that have less wear? Or just pass them on to someone who may be just getting started? I'm not expecting to turn them into Monarch 10EE class machines, just improve them a bit. After using the 9A, I'm not sure that either of them will get any future use in my shop. I've actually started looking for a SB 13" to slot between my 9" and 16" machines.

James

Last edited by a moderator: