- Joined

- Mar 31, 2019

- Messages

- 7

Hi,

I'm a draftsman and I have some drawings I made for my hobby. I was trying to get quotes to have the parts machined from people I know who own shops, but they don't even have the time to quote my dinky little parts. I have the material here already. My design is nearly 100%. All I need is to buy the machines to make my parts myself because I have decided, that for me, it simply isn't practical to rely on others to make my little hobby stuff anymore. It worked once in the past for a similar project, but I need to be independent now.

Even though I've designed parts for about 17 years now for others to machine, when it comes to buying the machines to make them myself I am feeling surprisingly lost and overwhelmed. I thought the best thing to do was include images of my drawings so you can suggest what lathe capacity to get and a mill to buy. I am looking to spend as much as $4,000 for both of these machines, but I'd like to spend less if I can get away with it. I won't be making parts often. The machines will see some very infrequent and light use (at least that's what I suspect for now).

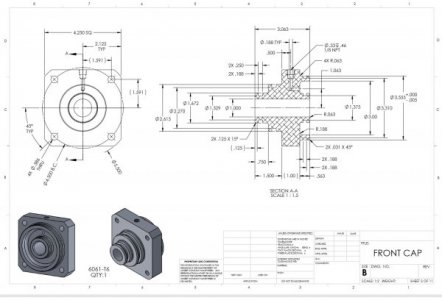

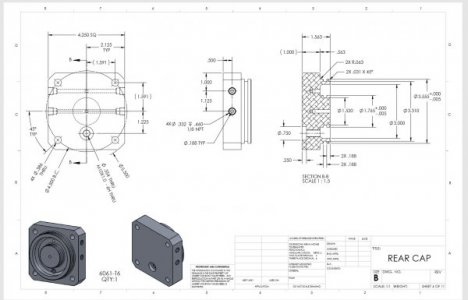

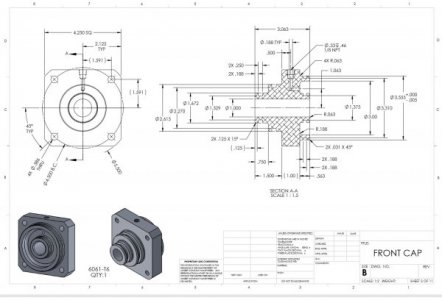

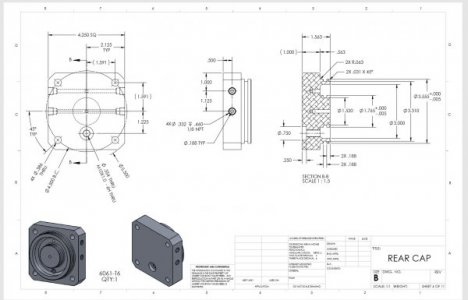

I have 6" round stock (short pieces 3 1/4 and 1 3/4" long) that I need to turn down to make the front and rear cap parts. I figured I'd turn them down to the 5.5" dia first, then machine the other diameters and then mill the flats. I would then do the holes. I suppose I could mill the flats first and chuck it up square in the lathe and maybe get away with a lathe that has a smaller chuck, but I'm afraid that could be cutting it too close. I'd be stuck at the absolute minimum of my lathe capacity needs, right?

I will be installing the machines in my garage. I have normal house electricity and I am a complete electrical noob, so I don't know what my amp or voltage capacity is. Whatever is the normal, standard weak sauce electricity is what I have, I'm sure.

I was thinking a Smithy 3 in 1, but those are almost $5,000 just for the machine and I'm not even sure I'd be happy having to break setups every single time I want to switch from lathe to mill etc. I think I'd be annoyed by that. I can see myself working on brackets for my project and getting all into it, and then deciding I'd like to take a break and turn some parts to do some experimenting on, but won't be able to. I'm leaning more toward a Grizzly lathe and mill, but I don't know what size lathe to get (chuck diameter that it comes with) for my parts. I assume a 3 jaw 6" chuck is what I need to machine 6" diameter stock, but what if I want to make something a bit larger at 6 1/2 or 7"? I wouldn't ever go larger than 7" I'm fairly certain, and I'd be happy enough if the largest I could work with was 6" diameter.

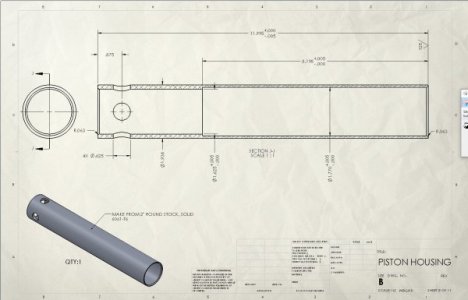

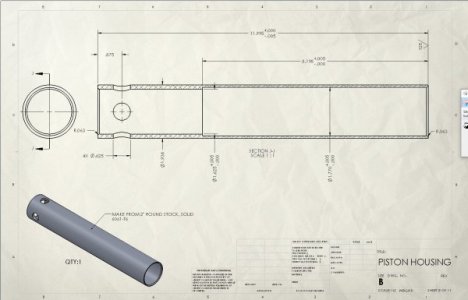

Sorry for the long post. See drawings below. Also, I think I'd need a boring bar for the piston housing. Is it reasonable to expect that I could machine that with a little boring bar? All parts are 6061-T6. I have a small 17-4 stainless part to make, but it's only 7/8" dia by about 3" long, so no big deal there.

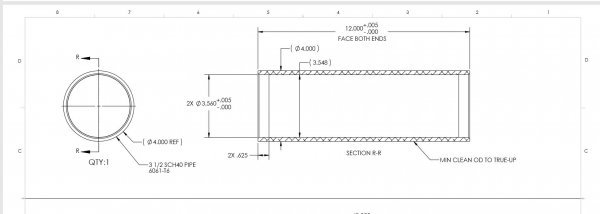

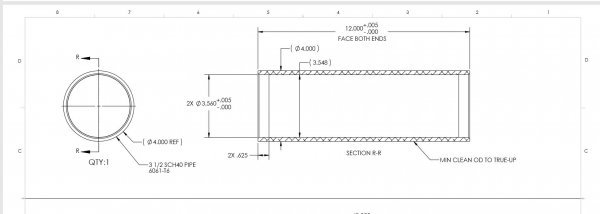

For the 3 1/2" SCH 40 part, would I need a steady rest to clean up the OD? The OD doesn't have to be clean, but I don't think it would turn true since that's going to be from SCH40 pipe, so I think I need to clean the OD first and then turn the small lengths in the ID so the parts will fit cleanly inside. Sound right? I always take the machining for granted but now I have to do it myself, lol. I also could make the piston housing from a thick walled pipe or tube. It doesn't have to be from solid stock as noted.

All of my projects will be of a similar nature, perhaps just the next size up for the pipe, so 4" SCH40. This would drive all the diameters about 1/2" larger and that would represent my maximum needed capacity in terms of diameter.

I'm a draftsman and I have some drawings I made for my hobby. I was trying to get quotes to have the parts machined from people I know who own shops, but they don't even have the time to quote my dinky little parts. I have the material here already. My design is nearly 100%. All I need is to buy the machines to make my parts myself because I have decided, that for me, it simply isn't practical to rely on others to make my little hobby stuff anymore. It worked once in the past for a similar project, but I need to be independent now.

Even though I've designed parts for about 17 years now for others to machine, when it comes to buying the machines to make them myself I am feeling surprisingly lost and overwhelmed. I thought the best thing to do was include images of my drawings so you can suggest what lathe capacity to get and a mill to buy. I am looking to spend as much as $4,000 for both of these machines, but I'd like to spend less if I can get away with it. I won't be making parts often. The machines will see some very infrequent and light use (at least that's what I suspect for now).

I have 6" round stock (short pieces 3 1/4 and 1 3/4" long) that I need to turn down to make the front and rear cap parts. I figured I'd turn them down to the 5.5" dia first, then machine the other diameters and then mill the flats. I would then do the holes. I suppose I could mill the flats first and chuck it up square in the lathe and maybe get away with a lathe that has a smaller chuck, but I'm afraid that could be cutting it too close. I'd be stuck at the absolute minimum of my lathe capacity needs, right?

I will be installing the machines in my garage. I have normal house electricity and I am a complete electrical noob, so I don't know what my amp or voltage capacity is. Whatever is the normal, standard weak sauce electricity is what I have, I'm sure.

I was thinking a Smithy 3 in 1, but those are almost $5,000 just for the machine and I'm not even sure I'd be happy having to break setups every single time I want to switch from lathe to mill etc. I think I'd be annoyed by that. I can see myself working on brackets for my project and getting all into it, and then deciding I'd like to take a break and turn some parts to do some experimenting on, but won't be able to. I'm leaning more toward a Grizzly lathe and mill, but I don't know what size lathe to get (chuck diameter that it comes with) for my parts. I assume a 3 jaw 6" chuck is what I need to machine 6" diameter stock, but what if I want to make something a bit larger at 6 1/2 or 7"? I wouldn't ever go larger than 7" I'm fairly certain, and I'd be happy enough if the largest I could work with was 6" diameter.

Sorry for the long post. See drawings below. Also, I think I'd need a boring bar for the piston housing. Is it reasonable to expect that I could machine that with a little boring bar? All parts are 6061-T6. I have a small 17-4 stainless part to make, but it's only 7/8" dia by about 3" long, so no big deal there.

For the 3 1/2" SCH 40 part, would I need a steady rest to clean up the OD? The OD doesn't have to be clean, but I don't think it would turn true since that's going to be from SCH40 pipe, so I think I need to clean the OD first and then turn the small lengths in the ID so the parts will fit cleanly inside. Sound right? I always take the machining for granted but now I have to do it myself, lol. I also could make the piston housing from a thick walled pipe or tube. It doesn't have to be from solid stock as noted.

All of my projects will be of a similar nature, perhaps just the next size up for the pipe, so 4" SCH40. This would drive all the diameters about 1/2" larger and that would represent my maximum needed capacity in terms of diameter.