Hi All

I'm thinking about making a couple punch and die sets for my two different pickup covers.

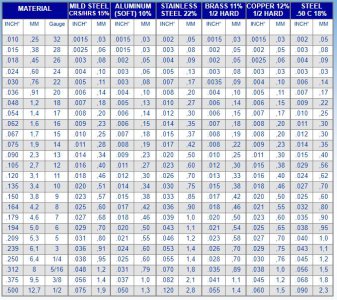

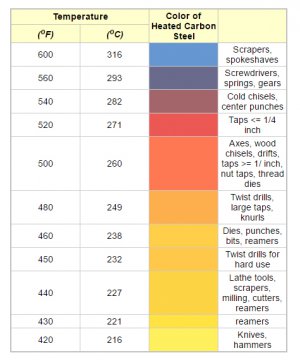

Currently, I just drill through the .020" nickel silver sheet but it leaves a rough result on the visible top side that I need to file down. Plus, I'm always looking to make processes more efficient as each cover requires 18 holes to be drilled. So I'm wondering if I can use mild steel rod to make my own punches and some mild steel plate for the dies.

Do you think the mild steel would easily punch through the .020" nickel silver plate?

I would make two punch sizes; 3/32" and 7/32". The punches would have threaded ends opposite the working end so that I could screw them into a steel plate with all 18 punches needed for a one-punch-and-done operation. Obviously the die underneath would have the 18 corresponding die holes. One challenge I see would be getting the mechanical alignment but I'm sure that's not too big a deal.

Lastly, is the working end of a punch flat or at an angle like a shear?

Any and all help and advice is greatly appreciated.

(pictured are two reject covers)

I'm thinking about making a couple punch and die sets for my two different pickup covers.

Currently, I just drill through the .020" nickel silver sheet but it leaves a rough result on the visible top side that I need to file down. Plus, I'm always looking to make processes more efficient as each cover requires 18 holes to be drilled. So I'm wondering if I can use mild steel rod to make my own punches and some mild steel plate for the dies.

Do you think the mild steel would easily punch through the .020" nickel silver plate?

I would make two punch sizes; 3/32" and 7/32". The punches would have threaded ends opposite the working end so that I could screw them into a steel plate with all 18 punches needed for a one-punch-and-done operation. Obviously the die underneath would have the 18 corresponding die holes. One challenge I see would be getting the mechanical alignment but I'm sure that's not too big a deal.

Lastly, is the working end of a punch flat or at an angle like a shear?

Any and all help and advice is greatly appreciated.

(pictured are two reject covers)