- Joined

- Sep 8, 2019

- Messages

- 4,392

I use a lot of pipe welding coupons + rectangular (or square) coupons, almost all of which are carbon steel.

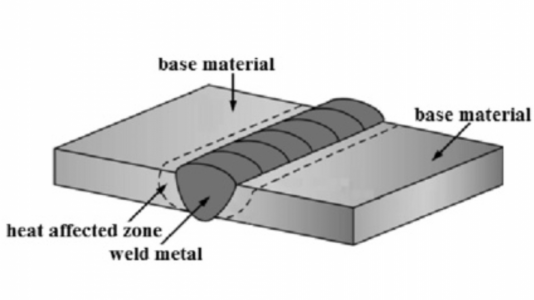

I already have it figured out how to re-use pipe & tubing welding coupons. After welding up the joint, I just chuck it up in the lathe, maybe cut out the HAZ, & make a fresh new pipe or tubing welding coupon.

With plate & sheet, I don’t have any good ideas. Looking at plate, I suppose one would maybe cut out the HAZ, & make a new (grooved) coupon (I do this on a milling machine). The trouble with this idea is that I don’t have a bandsaw or a cold saw, so I would be using a cutoff wheel (on an angle grinder) or an O/A cutting torch. I don’t mind having my coupons contaminated with HAZ or filler material; I cannot afford every coupon to be new material.

With sheet, I think that I would be time and money ahead to just buy new sheet coupons every time. For sheet, I like between .090” and 3/16”, & I pay the LSS to shear them because I don’t have a press brake.

I like 3” X 3” for sheet coupons. There are ways to get your money’s worth out of a bunch of squares: I start with a T-joint. Then I do another T-joint. Flip one T-joint upside down, & there is a lap joint. Do this twice, & you have a butt (or edge or corner) joint to join those together, & so on & so forth. I sure would like to know how I could do something constructive with this at the end other than scrap it. Maybe practice torch cutting & salvage a few good bits?

My main reason for making this post is to see if anybody had any ideas on how I could re-use plate coupons. The plate would probably be 1” thick & be a 6” X 6” square. This is *very* expensive material. I sure would like to buy only 1 or 2 plates, & then use them many, many times.

With my present financial situation combined with the high price of steel, I am not cutting out the HAZ.

I already have it figured out how to re-use pipe & tubing welding coupons. After welding up the joint, I just chuck it up in the lathe, maybe cut out the HAZ, & make a fresh new pipe or tubing welding coupon.

With plate & sheet, I don’t have any good ideas. Looking at plate, I suppose one would maybe cut out the HAZ, & make a new (grooved) coupon (I do this on a milling machine). The trouble with this idea is that I don’t have a bandsaw or a cold saw, so I would be using a cutoff wheel (on an angle grinder) or an O/A cutting torch. I don’t mind having my coupons contaminated with HAZ or filler material; I cannot afford every coupon to be new material.

With sheet, I think that I would be time and money ahead to just buy new sheet coupons every time. For sheet, I like between .090” and 3/16”, & I pay the LSS to shear them because I don’t have a press brake.

I like 3” X 3” for sheet coupons. There are ways to get your money’s worth out of a bunch of squares: I start with a T-joint. Then I do another T-joint. Flip one T-joint upside down, & there is a lap joint. Do this twice, & you have a butt (or edge or corner) joint to join those together, & so on & so forth. I sure would like to know how I could do something constructive with this at the end other than scrap it. Maybe practice torch cutting & salvage a few good bits?

My main reason for making this post is to see if anybody had any ideas on how I could re-use plate coupons. The plate would probably be 1” thick & be a 6” X 6” square. This is *very* expensive material. I sure would like to buy only 1 or 2 plates, & then use them many, many times.

With my present financial situation combined with the high price of steel, I am not cutting out the HAZ.

Last edited: