Hi,

I bought a Seig C3 lathe to play around with and convert to a CNC lathe. It has a 4" faceplate with a three hole pattern and an MT4 spindle bore. But all of my existing chucks have 1" or 1.125" x 8 TPI female threads. I have been searching for a faceplate I can bolt on that has a male 1" or 1'125" x 8 TPI thread so I can attach my existing chucks. I'm not finding anything that will work.

Does anyone have any suggestions of

1) where I can buy such a faceplace, or

2) some other way to be able to attach my threaded chucks.

Thanks,

Kent

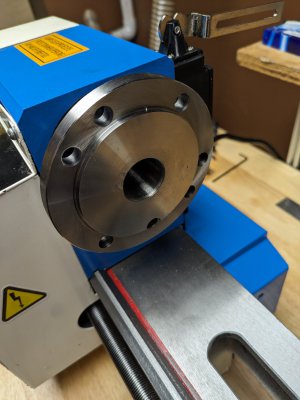

Update: I've attached some pictures of what I have been using (a Craftsman 101 with a threaded spindle), the chucks I hope to be able to use, and the faceplate on the Sieg lathe. I hope that helps to clarify things.

I bought a Seig C3 lathe to play around with and convert to a CNC lathe. It has a 4" faceplate with a three hole pattern and an MT4 spindle bore. But all of my existing chucks have 1" or 1.125" x 8 TPI female threads. I have been searching for a faceplate I can bolt on that has a male 1" or 1'125" x 8 TPI thread so I can attach my existing chucks. I'm not finding anything that will work.

Does anyone have any suggestions of

1) where I can buy such a faceplace, or

2) some other way to be able to attach my threaded chucks.

Thanks,

Kent

Update: I've attached some pictures of what I have been using (a Craftsman 101 with a threaded spindle), the chucks I hope to be able to use, and the faceplate on the Sieg lathe. I hope that helps to clarify things.

Attachments

Last edited: