- Joined

- Oct 19, 2020

- Messages

- 160

I've had my lathe a little less than a year. It seems that I have been spending more time getting set up than learning to use it. So this weekend I decided to make a two headed quarter. I give credit to mitxela who I found on uTube for giving me the idea.

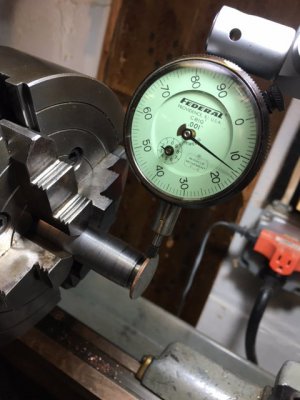

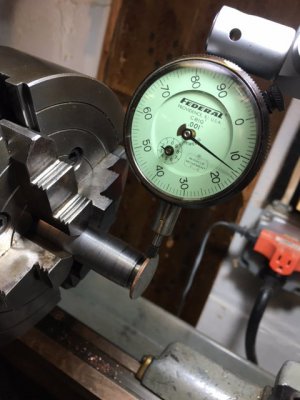

This exercise was good practice in using a 4 jaw chuck and a dial indicator for centering work in it. I would like to say that I measured everything but the truth is that there was a lot of eye balling.

Materials were cheap. About $.25 each for the main parts.

The first thing I had to do was to make a collet to hold the coin while I hollowed the insides out. I made mine from an old brass plumbing cap.

Then I used the collet in a 4 jaw chuck to hollow out the tails side of 2 quarters. One of the quarters was left with the outside of the coin in tact.

The other one was super glued to a rod so the outside could be machined off.

Before I machined the outside off, I needed to center the work. On my first try, I centered the rod, not the quarter. Ha. Ha.

I ended up with this.

I removed the no-edge quarter from the rod with some acetone. Then I had the pieces ready to glue together with a little epoxy.

And Bob's your uncle.

There is no better way for me to learn than to do. This project came out pretty good. Next time I will machine closer to the edge. Now I hope I don't accidentally spend it.

This exercise was good practice in using a 4 jaw chuck and a dial indicator for centering work in it. I would like to say that I measured everything but the truth is that there was a lot of eye balling.

Materials were cheap. About $.25 each for the main parts.

The first thing I had to do was to make a collet to hold the coin while I hollowed the insides out. I made mine from an old brass plumbing cap.

Then I used the collet in a 4 jaw chuck to hollow out the tails side of 2 quarters. One of the quarters was left with the outside of the coin in tact.

The other one was super glued to a rod so the outside could be machined off.

Before I machined the outside off, I needed to center the work. On my first try, I centered the rod, not the quarter. Ha. Ha.

I ended up with this.

I removed the no-edge quarter from the rod with some acetone. Then I had the pieces ready to glue together with a little epoxy.

And Bob's your uncle.

There is no better way for me to learn than to do. This project came out pretty good. Next time I will machine closer to the edge. Now I hope I don't accidentally spend it.