- Joined

- Oct 26, 2023

- Messages

- 88

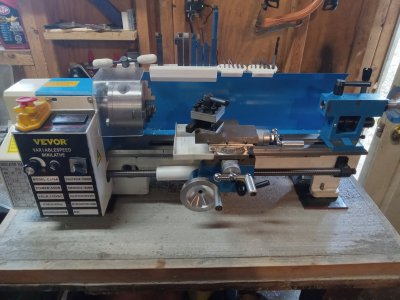

I pored a 2" high yield concrete slab on top of a heavy wooden work bench 2 weeks ago and finally got around to mounting my lathe to it.

I pored the slab because the bench top was almost 1/2" out of level and felt this was a good way to level the top and add some mass at the same time.

I was able to get the lathe dead nut level with only one thin shim on the tail stock end. I installed 1/4" flat plate under the mounting feet of the lathe to increase the foot print of the lathe. This may have been a waste of time? After getting the lathe level I installed the 3d printed accessories. chip guard, lead screw cover, tool holders etc.

My first project was to turn useable cross slide handles and get rid of the worthless stock ones.

The lathe performed better than I expected but there are a few issues I must address. Yesterday was a busy day in the shop.

I pored the slab because the bench top was almost 1/2" out of level and felt this was a good way to level the top and add some mass at the same time.

I was able to get the lathe dead nut level with only one thin shim on the tail stock end. I installed 1/4" flat plate under the mounting feet of the lathe to increase the foot print of the lathe. This may have been a waste of time? After getting the lathe level I installed the 3d printed accessories. chip guard, lead screw cover, tool holders etc.

My first project was to turn useable cross slide handles and get rid of the worthless stock ones.

The lathe performed better than I expected but there are a few issues I must address. Yesterday was a busy day in the shop.