- Joined

- Feb 2, 2013

- Messages

- 3,954

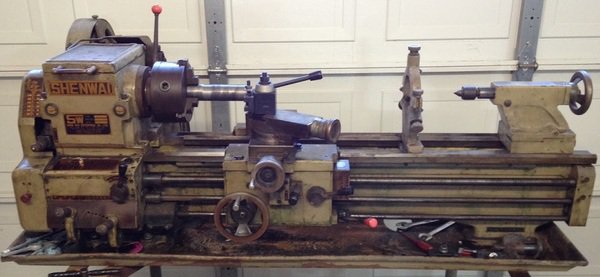

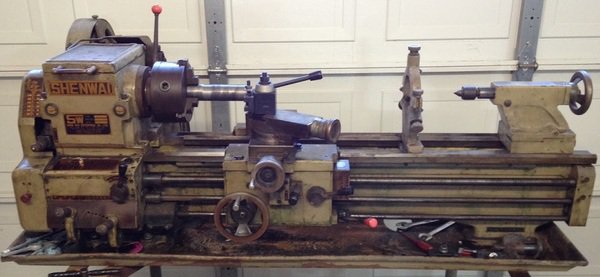

I Gaging DRO Installation

i got the i gaging dro's for my Shenwai SW900B lathe.

a close up of the scale installation, below

i got the 6" cross slide (Y axis) installed and the display positioned on my vfd enclosure.

to install,

lay out where the scale and dro slider will fit and be mounted.

(i removed the cross slide assembly)

drill holes & tap holes for the scale mount & dro slider ( i chose #8-32 x 1/4" screws- #29 tap drill)

(re-install cross slide)

install scale on cross slide & bolt the dro slider to the saddle

operate the cross slide and shim scale and/or dro slider as necessary to have a smooth, dragless, feel

install batteries and mount the display as necessary.

the unit works great in metric, decimal inch, and fractional inch

advertised accuracy is .002" per 6" of travel, i'll put it to the test....

stay tuned for the X axis in the next act!

i'll also be converting the units to battery free operation after the 2nd dro is installed...

thanks for reading!

i got the i gaging dro's for my Shenwai SW900B lathe.

a close up of the scale installation, below

i got the 6" cross slide (Y axis) installed and the display positioned on my vfd enclosure.

to install,

lay out where the scale and dro slider will fit and be mounted.

(i removed the cross slide assembly)

drill holes & tap holes for the scale mount & dro slider ( i chose #8-32 x 1/4" screws- #29 tap drill)

(re-install cross slide)

install scale on cross slide & bolt the dro slider to the saddle

operate the cross slide and shim scale and/or dro slider as necessary to have a smooth, dragless, feel

install batteries and mount the display as necessary.

the unit works great in metric, decimal inch, and fractional inch

advertised accuracy is .002" per 6" of travel, i'll put it to the test....

stay tuned for the X axis in the next act!

i'll also be converting the units to battery free operation after the 2nd dro is installed...

thanks for reading!

Last edited: