- Joined

- Sep 8, 2019

- Messages

- 4,392

I have this brand new knee mill. I’ve been using it about 2 weeks. When I first bought it, I *was* able to engage the power feed on the quill, and do so quite easily.

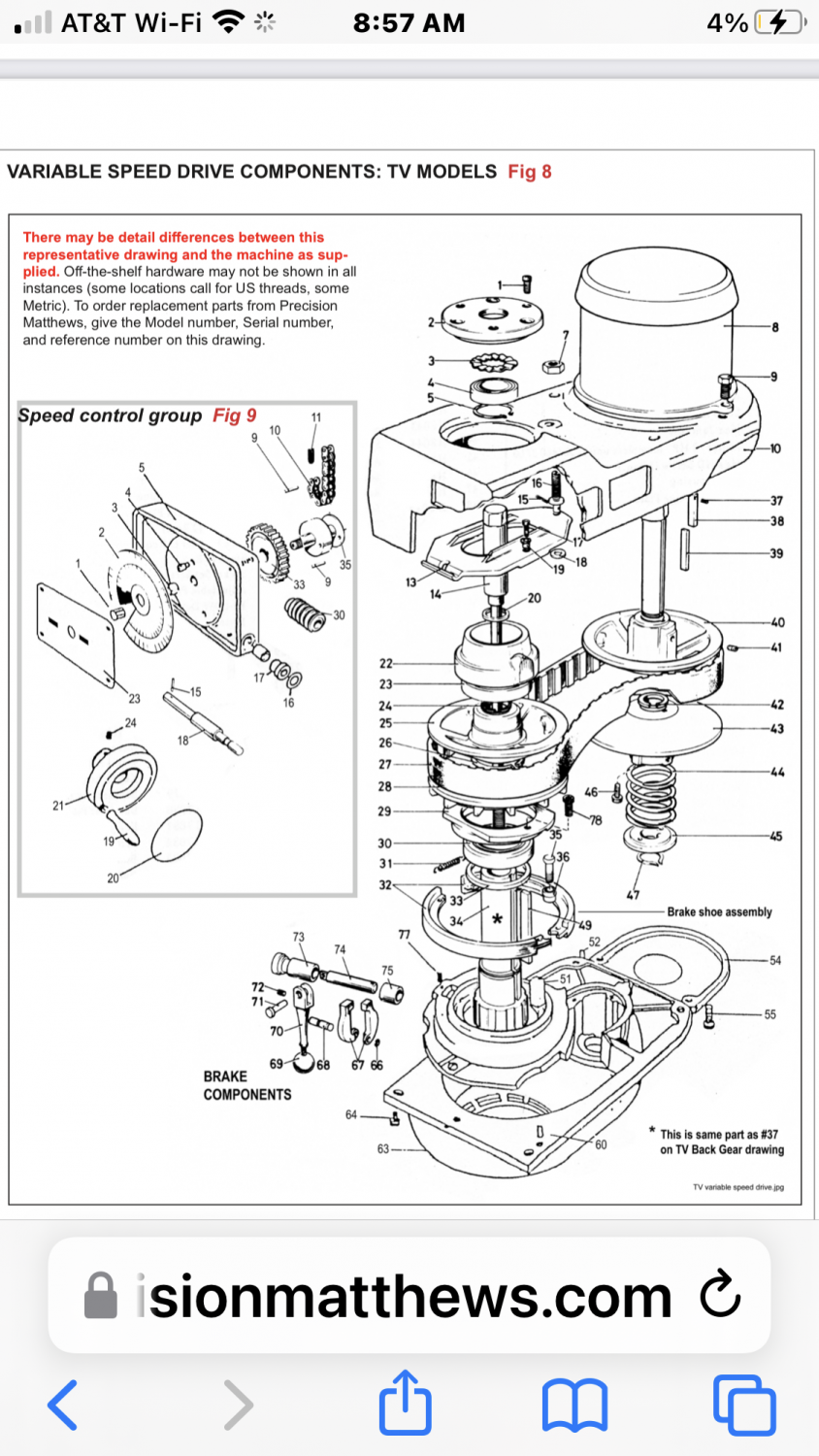

As it is now (I don’t know what changed), I need to use my hand to keep the lever (lever C in the Bridgeport drawing below) out, and then the power quill feed *will* function.

I also included pictures from the PM-1054 manual.

It seems to me that the clutch release is set way too loosely, and so I cannot engage the power feed (without holding the lever by hand) because the clutch has it permanently disengaged. I called Precision Matthews, and they also seem to think it was a clutch adjustment issue. If not that issue, then maybe some parts in there are not aligned.

Precision Matthews is going to get back to me, but he suggested that I post on here to see if anyone else has had this same problem.

I may have been ever so slightly rough on the machine at one point recently because I was using the power feed on the z-axis to move the table up as I was making a .060” radial cut in structural steel (A36 hot roll) while boring. The power feed was sent a lot higher than I wanted, and it crashed the tool such that it bent the cheap Chinese carbide tipped 1/2” shank boring bar.

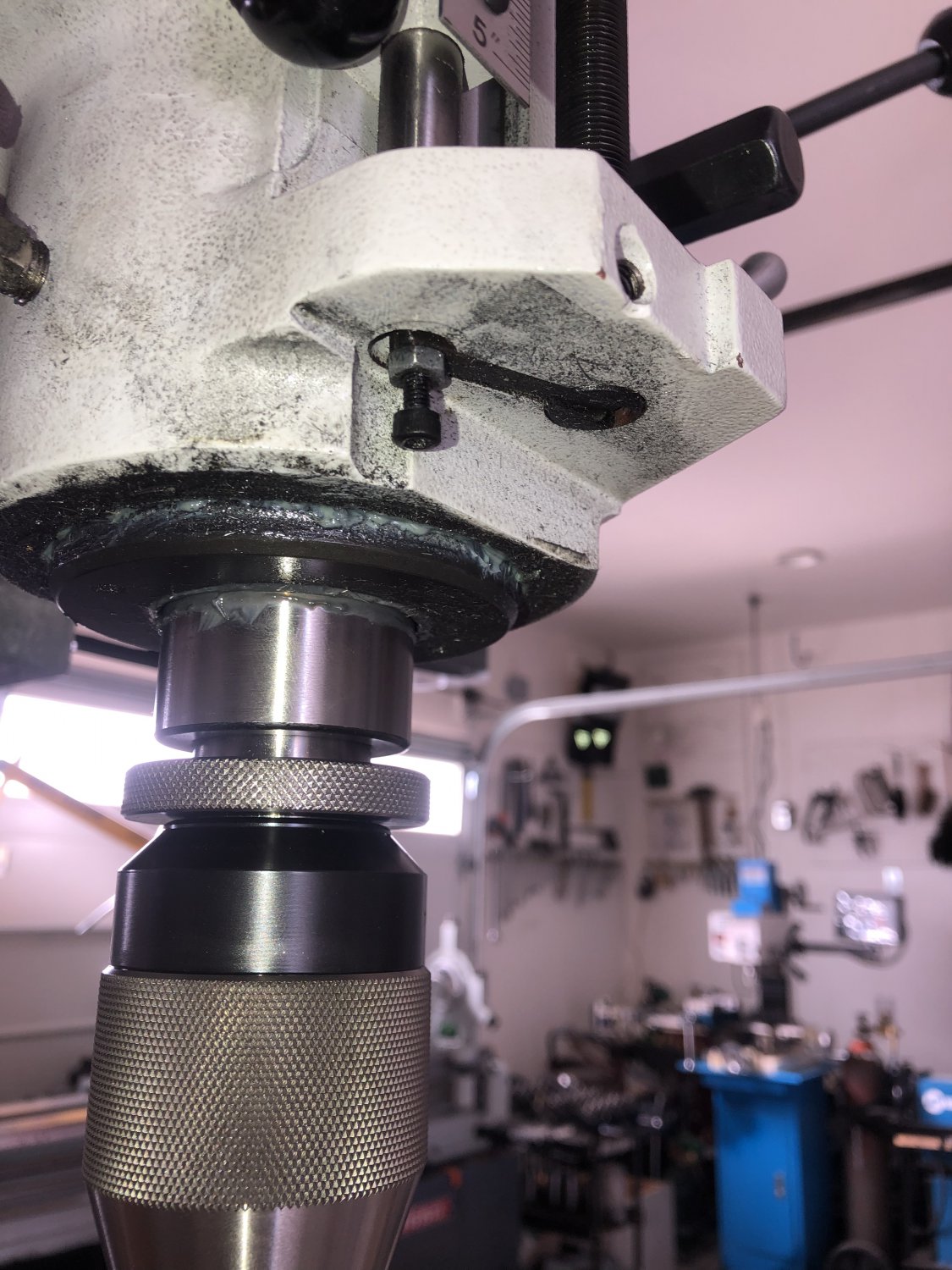

I am having trouble uploading the photo from the Bridgeport manual. I also uploaded a photo of the feed trip adjustment knob on my machine.

As it is now (I don’t know what changed), I need to use my hand to keep the lever (lever C in the Bridgeport drawing below) out, and then the power quill feed *will* function.

I also included pictures from the PM-1054 manual.

It seems to me that the clutch release is set way too loosely, and so I cannot engage the power feed (without holding the lever by hand) because the clutch has it permanently disengaged. I called Precision Matthews, and they also seem to think it was a clutch adjustment issue. If not that issue, then maybe some parts in there are not aligned.

Precision Matthews is going to get back to me, but he suggested that I post on here to see if anyone else has had this same problem.

I may have been ever so slightly rough on the machine at one point recently because I was using the power feed on the z-axis to move the table up as I was making a .060” radial cut in structural steel (A36 hot roll) while boring. The power feed was sent a lot higher than I wanted, and it crashed the tool such that it bent the cheap Chinese carbide tipped 1/2” shank boring bar.

I am having trouble uploading the photo from the Bridgeport manual. I also uploaded a photo of the feed trip adjustment knob on my machine.

Bend it back and use it if you can , boring bars don't have to be straight , they run eccentricly anyway .

Bend it back and use it if you can , boring bars don't have to be straight , they run eccentricly anyway .