-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I bought some new tool bits for my 618 and the results puzzle me...

- Thread starter dfwcnc

- Start date

- Joined

- Aug 7, 2012

- Messages

- 23

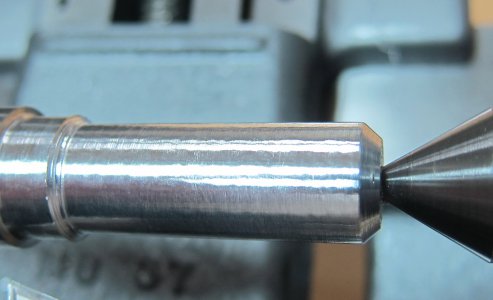

After adjusting speed (up and down), angle of cut (narrow to wide), I can't figure out what in the world is going on here. The warbly look is driving me crazy to solve. Is it the carbide inserts?

Thanks...

Maybe the tool is a tad too low, the feed is too aggressive, and the tip is catching and snapping back up, causing inconsistent depth-of-cut. Maybe chatter is being introduced by something on the compound not being strictly locked down. Maybe the work is hardened. You may want to try a HSS tool and dress it very sharp with some india stones. May want to try some lubricant. Reduce the speed, increase the feed. Seems like you've got enough feed though.

I have infinit control over speed, which is tied to feed, and it had no effect. Further, I used lube, no difference. The piece is 8 inches long with a great live center. I am wondering if I may need more support on the work piece, or it may be the carbide bits. Very strange. It is 6061 aluminum that I've used on my CNC mill with no problems. I am perplexed.

Maybe the tool is a tad too low, the feed is too aggressive, and the tip is catching and snapping back up, causing inconsistent depth-of-cut. Maybe chatter is being introduced by something on the compound not being strictly locked down. Maybe the work is hardened. You may want to try a HSS tool and dress it very sharp with some india stones. May want to try some lubricant. Reduce the speed, increase the feed. Seems like you've got enough feed though.

- Joined

- Aug 7, 2012

- Messages

- 23

Hmm. Maybe the surface is/was oxidized and the depth of cut was insufficient to prevent galling. Maybe now you've broken through the surface it'll smooth out. Maybe a sharper hook angle is necessary if you can manage it with the tooling you have. Really sharp HSS should do the trick or chuck up a cheap steel bolt and see what the carbide does with it. I'm curious to know how it is resolved.

I have infinit control over speed, which is tied to feed, and it had no effect. Further, I used lube, no difference. The piece is 8 inches long with a great live center. I am wondering if I may need more support on the work piece, or it may be the carbide bits. Very strange. It is 6061 aluminum that I've used on my CNC mill with no problems. I am perplexed.

I believe it needs HSS.

However, taking off the auto feed and kicking-up the speed, taking small bites, and manually feeding it slowly, I managed very good results, but not perfect. I think there is some truth to using these carbide bits on this lathe for some reason. When using them on my CNC, I can go to 8,000 rpm and take a thou off and get a mirror. So, it has to be speed and feed. If I can't get the speed, then I need to slow down the feed to get it to work. HSS would be best.

I may be selling the lathe to begin a project on a SB so I am holding off on any more tool bits, especially high dollar ones.

However, taking off the auto feed and kicking-up the speed, taking small bites, and manually feeding it slowly, I managed very good results, but not perfect. I think there is some truth to using these carbide bits on this lathe for some reason. When using them on my CNC, I can go to 8,000 rpm and take a thou off and get a mirror. So, it has to be speed and feed. If I can't get the speed, then I need to slow down the feed to get it to work. HSS would be best.

I may be selling the lathe to begin a project on a SB so I am holding off on any more tool bits, especially high dollar ones.

Hmm. Maybe the surface is/was oxidized and the depth of cut was insufficient to prevent galling. Maybe now you've broken through the surface it'll smooth out. Maybe a sharper hook angle is necessary if you can manage it with the tooling you have. Really sharp HSS should do the trick or chuck up a cheap steel bolt and see what the carbide does with it. I'm curious to know how it is resolved.

The 618 really isn't heavy enough for carbide. Try HSS and you'll see a much better finish. If you want to stay with inserts try AR Warner - they make HSS inserts.

Chrispy

- Joined

- Nov 16, 2012

- Messages

- 5,596

You can cut AL with carbide just fine... What's the diameter of the workpiece? Any chance you can show a pic of the bit setup?

I've had that same symptom but for the life of me don't remember what I did to fix it. -No rocket science... just proper bit positioning and SFM.

I've had that same symptom but for the life of me don't remember what I did to fix it. -No rocket science... just proper bit positioning and SFM.