- Joined

- Jul 29, 2013

- Messages

- 55

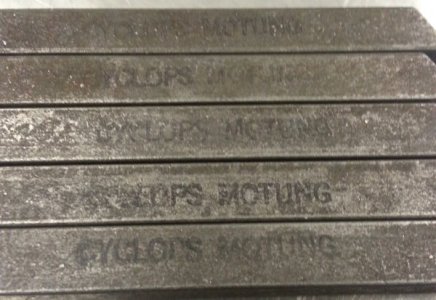

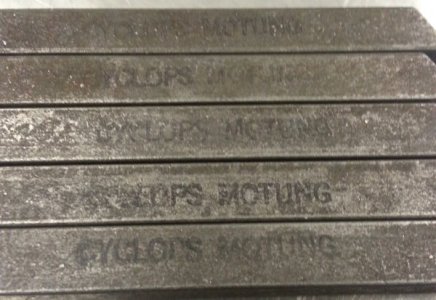

I recently purchased a box of 3/8" tool bits and have a few questions.

Some have ground surfaces, others not ground. What is the difference? I assume the ground cost a little more to manufacture.

Rex and Vasco are brand names aren't they?

What about AL-LMW, what does that designate, are they M2?

Curious about the BS script. Would that be Brown & Sharpe?

By the way, I have Mikey to thank or blame for this. After reading his very detailed posts on tool bit grinding I am all in. Thanks Mikey.

Some have ground surfaces, others not ground. What is the difference? I assume the ground cost a little more to manufacture.

Rex and Vasco are brand names aren't they?

What about AL-LMW, what does that designate, are they M2?

Curious about the BS script. Would that be Brown & Sharpe?

By the way, I have Mikey to thank or blame for this. After reading his very detailed posts on tool bit grinding I am all in. Thanks Mikey.