- Joined

- Dec 18, 2019

- Messages

- 7,428

It seems that most of my lathe tools that I have ground end up chipping, or micro-fracturing. I've had one crack not at the tip, but at 1/16" below the tip. For the most part, I just re-hone if I can, or give it a quick touch to 100 grit ceramic belt and re-hone. This last one seemed to crack along the cutting edge of a square cut lathe tool bit. It is giving a ribbed, grooved finish, as opposed to a nice shiny one. This tool bit was used on 6061, so it's not on anything hard. The tools are kept in QCTP carriers which are in turn in Schaller boxes, so they don't hit anything. I'm not ramming the bit into the work, the cuts aren't super deep.

Anyone have a suggestion as to why this might be happening? The edges don't wear, they seem to chip. Right now I'm getting significantly better surface finish with TCGT carbide than with HSS. And the HSS isn't lasting long. It could be something I'm doing, but I'm at a loss at what that might be.

HSS on the left, TCGT carbide on the right.

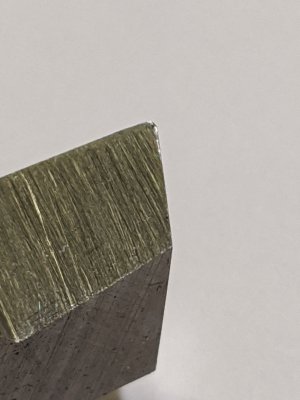

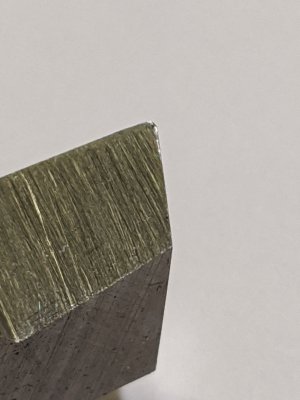

Trying to photograph the tool tip. Here's one. I was using WD40. One can see a little aluminum on the tip, but behind the tip is a bright area, which is the edge breaking off.

Having trouble with getting the other view in focus. Not possible with my phone camera. I can see it in my stereo microscope.

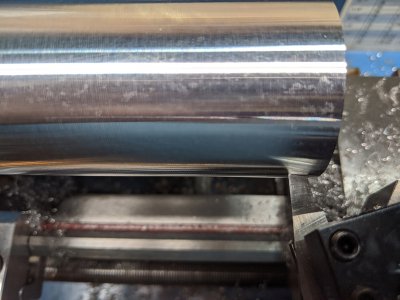

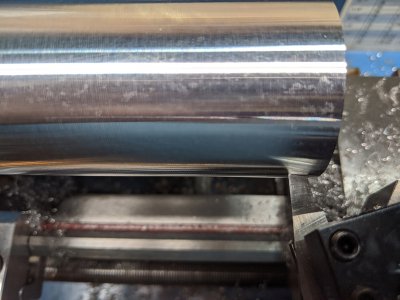

Here is a view of the tool on the lathe.

Any clues I could pursue? Thanks!

Anyone have a suggestion as to why this might be happening? The edges don't wear, they seem to chip. Right now I'm getting significantly better surface finish with TCGT carbide than with HSS. And the HSS isn't lasting long. It could be something I'm doing, but I'm at a loss at what that might be.

HSS on the left, TCGT carbide on the right.

Trying to photograph the tool tip. Here's one. I was using WD40. One can see a little aluminum on the tip, but behind the tip is a bright area, which is the edge breaking off.

Having trouble with getting the other view in focus. Not possible with my phone camera. I can see it in my stereo microscope.

Here is a view of the tool on the lathe.

Any clues I could pursue? Thanks!