- Joined

- Mar 14, 2013

- Messages

- 443

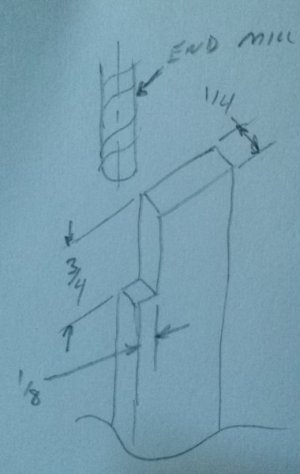

This is a semi hypothetical question, the milling operating I had in mind turned out to be unnecessary, but the question remains: say you need to mill some amount off the side of a workpiece, considerably deeper than wide. For example, maybe 1/8" cut by 3/4" deep. Setup restrictions prevent laying it over and cutting it 1/8" deep by 3/4" wide. Anyway, one could make a shallow cut the full 1/8" wide, advance the spindle, and repeat until the 3/4" depth is reached, or position the end mill at the full 3/4" depth and make repeated shallow cuts with the side of the cutter until the 1/8" is reached.

Which would you do, and why?

Which would you do, and why?