- Joined

- Mar 27, 2022

- Messages

- 504

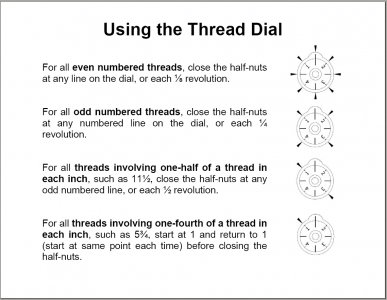

I don’t have any need currently to thread but I haven’t threaded with this lathe. It’s an early Sheldon 10”. The thread dial is 1-4 if I remember correctly. I don’t think I saw any chart on the machine for when to engage for selected tpi’s. Any tips on how to figure that out?