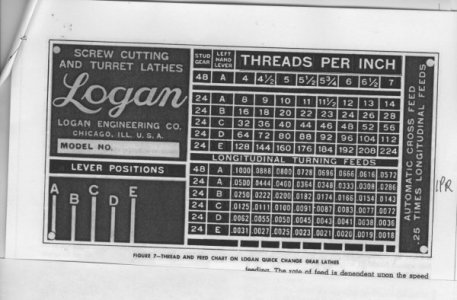

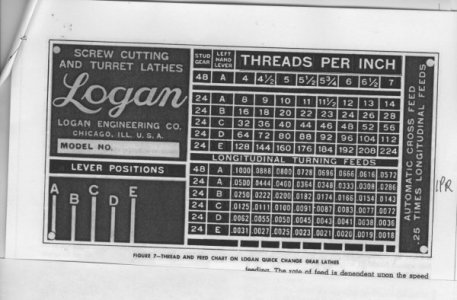

The units in your chart is in inches per revolution. I think you are trying to determine which feed rate to use for a given material, no? The answer depends on a number of factors - RPM, material, size, depth of cut, etc. Simplest answer is to look up the recommended feed rate for your material in a chart and set feed for that. For example, most charts will tell you to rough 12L14 at 0.006" per rev so you set your lever to 24D to cut at 0.006"/rev.

With that said, all the charts are for industrial applications. Basically, the recommended feed rates are to enable maximum metal removal rates. Some, not all, charts take into account the HP of the lathe. Rigidity of the lathe is NOT considered but is assumed to be adequate to handle feed at the rate they recommend. I will tell you now that your lathe does not fall into that category.

What I do is look at the chart for a baseline setting in IPR for the material you have and set it, then do test cuts. My lathe is only an 11" but it is very rigid for its size and has a 2HP motor. I try the cut at the DOC I want and at the speed I chose and see how the lathe handles that feed while roughing and finishing. I then alter the feed depending on how the lathe responds to the cut and it is almost always different than the recommended feed rate. Once I figure out what works best for that material using a particular cutter set for DOC-X at RPM-Y, I make note of it for future reference. Over time, you will build up a list that is actually useful for you because the charts are usually not useful.