Annealing would be appropriate. I think I would take a piece of round stock just shy of the ID, and shape a full radius end on it. Working all hand held, tap lightly and put a little pressure in the "straightening" direction. Use a little grease on the half-ball shape and it should not take much force. Make the end of the rod as smooth as possible. The rod will keep the tubing from collapsing and keep it all round. You shouldn't have to anneal it beyond the initial process. That may not be absolutely necessary, but since the temper is unknown, but we do know that it work hardens from bending, we can safely say it is harder than it originally was and there could be a risk of cracking if it was already at a hard temper. Don't heat it and try to work it while hot.

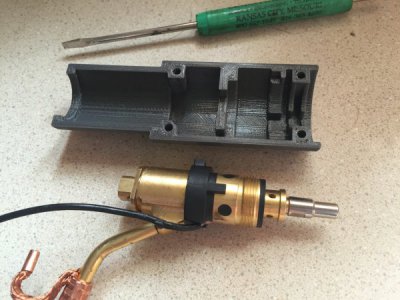

How straight is "straight" in this instance? How much pressure is on it? It looks like a bit of gas plumbing from a welder. Is that a solenoid operated valve it goes into?