- Joined

- Feb 23, 2016

- Messages

- 480

I am making a manifold for compressed air, and need advice on how to thread mill NPT threads, specifically 1/4" - 18. I looked up the thread and the small diameter is 0.4774", the large dia is 0.4916", and the length of useful thread is 0.4018". A drill size of 7/16" is recommended.

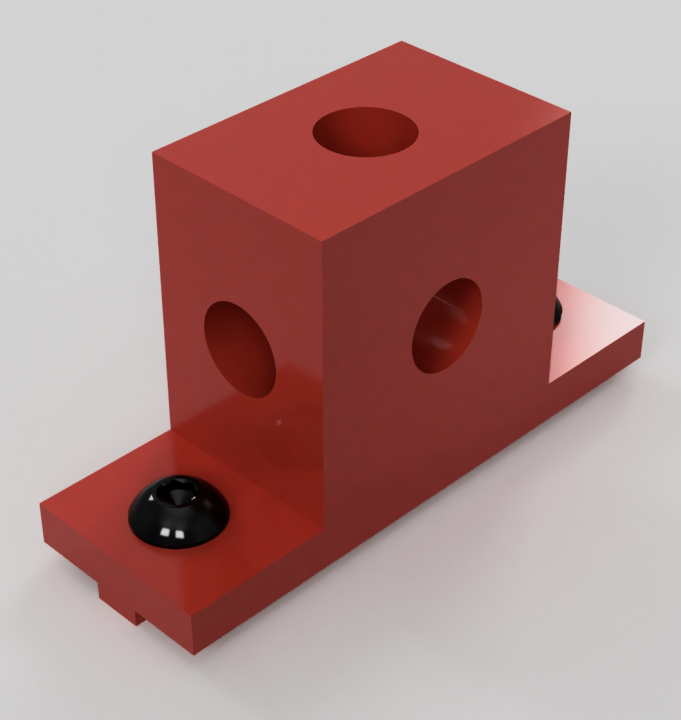

This is what the manifold will look like:

The hole on the front left will punch through and there will be one inlet on top, and three outlets on the front, right, and left walls. These are the 4 holes that I want to tap NPT 1/4" - 18 to attach air fittings. The two tabs will be used to attach to 8020 1010 profile.

I have done thread milling for 1/4" - 20 holes and liked it a lot more than tapping. I have a Tormach #34694 threadmill (for 1/4" and M6 threads) and the Tormach #34696 (for 3/8, 7/16, 1/2, M10, M12, M14 threads), which is what I plan to use.

How do I drill the tapered starter hole? Should I use a boring bar and drill a hole exactly to teh small diamater? Does anyone have any experience to share on how to do this type of thread with a threadmill?

This is what the manifold will look like:

The hole on the front left will punch through and there will be one inlet on top, and three outlets on the front, right, and left walls. These are the 4 holes that I want to tap NPT 1/4" - 18 to attach air fittings. The two tabs will be used to attach to 8020 1010 profile.

I have done thread milling for 1/4" - 20 holes and liked it a lot more than tapping. I have a Tormach #34694 threadmill (for 1/4" and M6 threads) and the Tormach #34696 (for 3/8, 7/16, 1/2, M10, M12, M14 threads), which is what I plan to use.

How do I drill the tapered starter hole? Should I use a boring bar and drill a hole exactly to teh small diamater? Does anyone have any experience to share on how to do this type of thread with a threadmill?

Last edited: