-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How To De-magnetize Electronic Calipers

- Thread starter sanddan

- Start date

- Joined

- Nov 27, 2012

- Messages

- 7,912

I run my Mitutoyo digital calipers over a demagnetizer. I've seen talk where there are concerns about causing damage to it. Some recommend removing the battery. If you send calipers to Mitutoyo for repair, they automatically demagnetize them. I've never had a problem demagnetizing any of my calipers.

- Joined

- Aug 15, 2013

- Messages

- 2,505

- Joined

- Feb 1, 2015

- Messages

- 9,958

One method that I have used, if you have a soldering gun is to replace the standard tip with a piece of 10 awg. copper wire to make a loop of about 2" in diameter. Turn on the gun to the 140 watt position and pass the jaws of the calipers into and out of the loop. Do not release the trigger until you have removed the calipers from the vicinity of the loop. This should demagnetize them.

The wire will heat up so act quickly and don't touch anything heat sensitive to the wire. I use 10 awg wire to make my own soldering tips rather than buying the pre-made tips.

In theory, you should be able to make multiple loops of the same gauge wire since the magnetic flux is proportional to the number of turns times the current flowing and the resistance of the wire is proportional to the length of wire and therefore current will be inversely proportional to the number of turns so, for constant voltage, the flux is a constant.

Another method involves an old CRT TV or monitor. They all had a degaussing circuit consisting of a coil of wire wrapped around the perimeter of the CRT which was energized when the set was turned on. One of those coils run with a Variac would enable you to degauss a larger item. Again, they were made for short term use so this is a get in/get out quickly kind of thing.

Finally, I had an old cassette tape eraser that used a rotating permanent magnet.The rotation creates the changing magnetic field instead of the alternating current. To use, you start the magnet(s) rotating and slowly bring your tool in as close as possible and withdraw it slowly. Stop the rotation after the tool is removed from the vicinity. With some of the rare earth magnets available now, you could probably make a degausser by epoxying two magnets to a steel bar or plate that has an central axle you can mount in a lathe or mill. It would be best to put it magnets in a pocket or use other restraints to prevent them from being thrown out by centrifugal force and become unguided missiles. Based on the tape demagnetizer, you will not need high rpm. I would think that 200rpm would work.

The principle behind all demagnetizers is that you have to use a spatially magnetic field strong enough to align the domains in opposition to the existing magnetism. By pulling the object out of the varying magnetic field, the domains are random ly aligned again and the object is demagnetized.

The wire will heat up so act quickly and don't touch anything heat sensitive to the wire. I use 10 awg wire to make my own soldering tips rather than buying the pre-made tips.

In theory, you should be able to make multiple loops of the same gauge wire since the magnetic flux is proportional to the number of turns times the current flowing and the resistance of the wire is proportional to the length of wire and therefore current will be inversely proportional to the number of turns so, for constant voltage, the flux is a constant.

Another method involves an old CRT TV or monitor. They all had a degaussing circuit consisting of a coil of wire wrapped around the perimeter of the CRT which was energized when the set was turned on. One of those coils run with a Variac would enable you to degauss a larger item. Again, they were made for short term use so this is a get in/get out quickly kind of thing.

Finally, I had an old cassette tape eraser that used a rotating permanent magnet.The rotation creates the changing magnetic field instead of the alternating current. To use, you start the magnet(s) rotating and slowly bring your tool in as close as possible and withdraw it slowly. Stop the rotation after the tool is removed from the vicinity. With some of the rare earth magnets available now, you could probably make a degausser by epoxying two magnets to a steel bar or plate that has an central axle you can mount in a lathe or mill. It would be best to put it magnets in a pocket or use other restraints to prevent them from being thrown out by centrifugal force and become unguided missiles. Based on the tape demagnetizer, you will not need high rpm. I would think that 200rpm would work.

The principle behind all demagnetizers is that you have to use a spatially magnetic field strong enough to align the domains in opposition to the existing magnetism. By pulling the object out of the varying magnetic field, the domains are random ly aligned again and the object is demagnetized.

- Joined

- Nov 27, 2012

- Messages

- 7,912

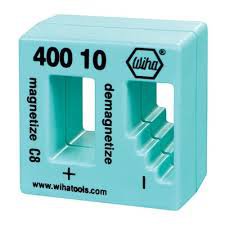

I have a couple of those Wiha demagnetizers, the older dark green ones. They do work well on some screwdrivers, especially Wiha screwdrivers but that's about it. The generic copies suck.

For larger tools & what I use for calipers, I use a cheap import demagnetizer from Enco (got it on sale for $40 + 20% off that). There's more expensive quality ones but this one hasn't failed me yet. It works very well, one wave across it & it's done. It has demagnetized everything I've needed to date.

(You don't actually set parts on it to demagnetize, below was just for the pic when I took it)

For larger tools & what I use for calipers, I use a cheap import demagnetizer from Enco (got it on sale for $40 + 20% off that). There's more expensive quality ones but this one hasn't failed me yet. It works very well, one wave across it & it's done. It has demagnetized everything I've needed to date.

(You don't actually set parts on it to demagnetize, below was just for the pic when I took it)

- Joined

- Feb 8, 2014

- Messages

- 11,176

I run my Mitutoyo digital calipers over a demagnetizer. I've seen talk where there are concerns about causing damage to it. Some recommend removing the battery. If you send calipers to Mitutoyo for repair, they automatically demagnetize them. I've never had a problem demagnetizing any of my calipers.

I have the same problem. I have been afraid to try it, I thought the scale was magnetic. I'll give it a try.

- Joined

- Dec 8, 2013

- Messages

- 2,651

Excellent! How many turns?Here is what I use. I made a number of turns on a form so that heating wouldn't be an issue. Works great.

View attachment 99442

David

- Joined

- Feb 8, 2014

- Messages

- 11,176

I run my Mitutoyo digital calipers over a demagnetizer. I've seen talk where there are concerns about causing damage to it. Some recommend removing the battery. If you send calipers to Mitutoyo for repair, they automatically demagnetize them. I've never had a problem demagnetizing any of my calipers.

I'm happy to report that my calipers are demagnetized and suffered no damage in the process.

- Joined

- Nov 18, 2012

- Messages

- 1,352

Excellent! How many turns?

ID of form in is 1.75" 6 turns of 16 awg solid.

David