- Joined

- Aug 29, 2019

- Messages

- 1,076

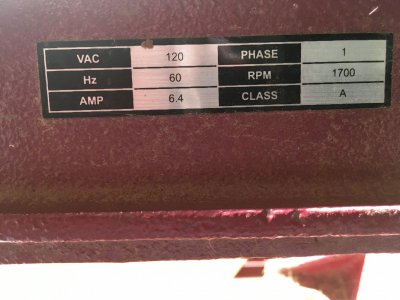

Today I bought a used Chicago Electric horizontal band saw. The motor is fried like DEEP fried. The plastic cooling fan was melted and the coils are all testing bad with a megger. It would not even rotate until I took it apart. Surprisingly the bearings apear to be okay and the plastic seals are not bad but I do not believe there is any hope in restoring the motor to working since all the insulation in the coil slots is melted. I can't even find a model number or horsepower rating on the motor because it is so cheap they didn't even put the tag on the motor they put it on the casting of the saw and itis a sticker not a metal tag or plate.

Now to the question How does it do it? There is no centrifigual switch to disengage the start windings when the motor reaches full RPM which is 1700rpm. I see no evidence of a magic electronic device to switch to run mode. The housing of the capacitor is plastic, and it looks like an overheated black ice cream cone.

So is the magic inside the capacitor or what? Also I see no evidence of a thermal over temp switch. Story of my life now that I know how single-phase motors work, they change the rules on me.

So, How does it do it?

Now to the question How does it do it? There is no centrifigual switch to disengage the start windings when the motor reaches full RPM which is 1700rpm. I see no evidence of a magic electronic device to switch to run mode. The housing of the capacitor is plastic, and it looks like an overheated black ice cream cone.

So is the magic inside the capacitor or what? Also I see no evidence of a thermal over temp switch. Story of my life now that I know how single-phase motors work, they change the rules on me.

So, How does it do it?