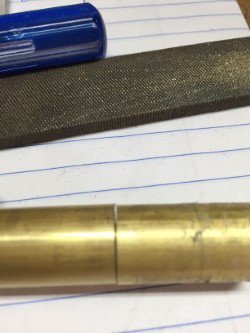

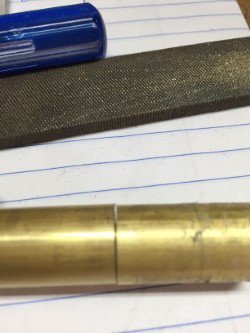

I am making a pen out of brass for my dad's 60th Bday. The part on the right is the cap with a threaded section to help apply counter pressure to the ink cartridge. The part on the left is the pen body. I have already tried to file down some of the male threaded section thinking maybe it was too long. It helped close the gap some but not all the way. I am trying to be careful because I dont want there to be any play so that when writing pressure is applied the ink cartridge shifts up and down.

Do I chuck up the pen body and take a few thousandths off of it? My plan was to turn the entire pen (when finished) to the same diameter because you can see it is off some. I assume this is because of the tolerances in my Chinese made 4 jaw chuck (I really need to get a 4" 3 jaw). Between that and my dial indicator I can only get 1-2 thousandths off.

Do I chuck up the pen body and take a few thousandths off of it? My plan was to turn the entire pen (when finished) to the same diameter because you can see it is off some. I assume this is because of the tolerances in my Chinese made 4 jaw chuck (I really need to get a 4" 3 jaw). Between that and my dial indicator I can only get 1-2 thousandths off.