- Joined

- Oct 29, 2012

- Messages

- 1,387

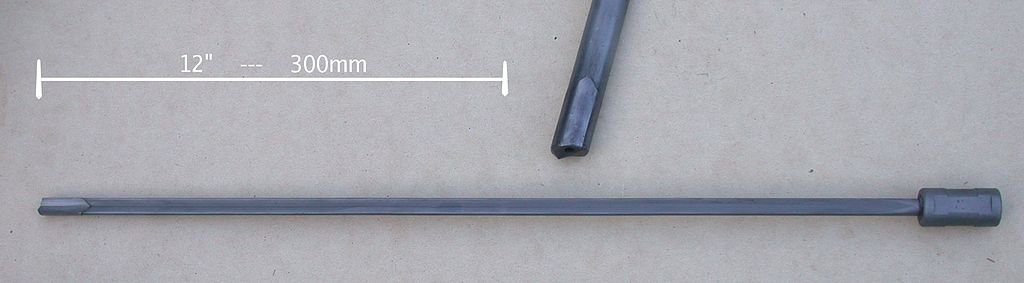

A friend brought me this cheap little .22lr pistol, wanted me to come up with a way to adapt a suppressor to it. This is what I came up with. Turned down the end of the barrel and threaded it 7/16-20, then made this adapter with a 7/16-20 internal thread and a 1/2-28 outer thread. Worked well, after going through 4 failed blanks where the bore was crooked. Drill bit wander. How do I get better than a 20% success rate? I have somehow avoided learning this lesson; everything I've drilled/bored thus far has been larger diameter. The bigger bits don't wander as bad, and I'm usually going in with a boring bar afterwards anyway so it doesn't matter. I plan to do this again and I want to do it better, more predictable outcome. Is there a different tool I should be using other than a drill bit? I know a better ground drill drills a straighter hole but what drills a straight hole?