- Joined

- Sep 8, 2019

- Messages

- 4,392

I just burned up a 250A-rated CK Worldwide TIG torch. The torch was 3 years old. The manner in which it failed was that the red hose was burnt, shrunken, and thus obstructed.

The red hose (that has the welding cable in it) had gotten very hot the last time that I used it (which was 12 months ago). What I remember from the last time that I used it was that I was using 210A. My machine is a Dynasty 210DX, and I have never had it shut off due to overworking it. That is, I have never come up against the duty cycle.

At some point, I am going to need to determine if my Miller CoolMate 1.3 is functioning. Has anybody ever been in this position?

I would hate to buy a brand new TIG torch, and have it burn up because the water cooler is not circulating.

To recap, when I took the TIG torch out of storage, the red hose was burnt and shrunken. If it is the case that my water cooler is fine, the water would have not been able to pass through this damaged red hose.

The red hose (that has the welding cable in it) had gotten very hot the last time that I used it (which was 12 months ago). What I remember from the last time that I used it was that I was using 210A. My machine is a Dynasty 210DX, and I have never had it shut off due to overworking it. That is, I have never come up against the duty cycle.

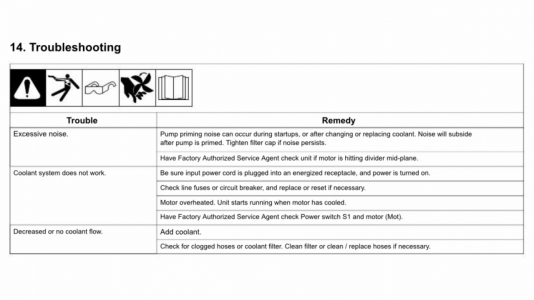

At some point, I am going to need to determine if my Miller CoolMate 1.3 is functioning. Has anybody ever been in this position?

I would hate to buy a brand new TIG torch, and have it burn up because the water cooler is not circulating.

To recap, when I took the TIG torch out of storage, the red hose was burnt and shrunken. If it is the case that my water cooler is fine, the water would have not been able to pass through this damaged red hose.

Last edited: