- Joined

- Jul 31, 2014

- Messages

- 27

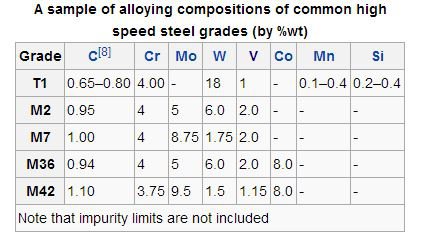

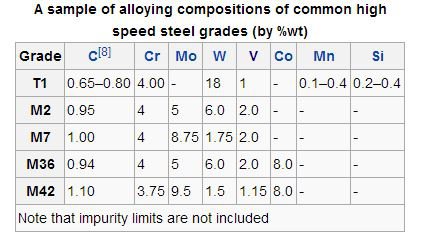

From Wikipedia on High Speed Steel

When tools are advertised as HSS, I should assume they are using M2 grade HSS, correct ?

When tools are advertised as "cobalt", unless they specifically say M42, I should assume they are M36, correct ?

M2 is molybdenum based high-speed steel in tungsten–molybdenum series. The carbides in it are small and evenly distributed. It has high wear resistance. After heat treatment, its hardness is the same as T1, but its bending strength can reach 4700 MPa, and its toughness and thermo-plasticity are higher than T1 by 50%. It is usually used to manufacture a variety of tools, such as drill bits, taps and reamers. Its decarburization sensitivity is a little bit high.[9]

M36 is similar to M2, but with 8% cobalt added. The addition of cobalt increases heat resistance. M36 is also known as HSSE or HSS-E.

M42 is a molybdenum-series high-speed steel alloy with an additional 8% cobalt. It is widely used in metal manufacturing because of its superior red-hardness as compared to more conventional high-speed steels, allowing for shorter cycle times in production environments due to higher cutting speeds or from the increase in time between tool changes. M42 is also less prone to chipping when used for interrupted cuts and costs less when compared to the same tool made of carbide. Tools made from cobalt-bearing high speed steels can often be identified by the letters HSS-Co.

When tools are advertised as HSS, I should assume they are using M2 grade HSS, correct ?

When tools are advertised as "cobalt", unless they specifically say M42, I should assume they are M36, correct ?