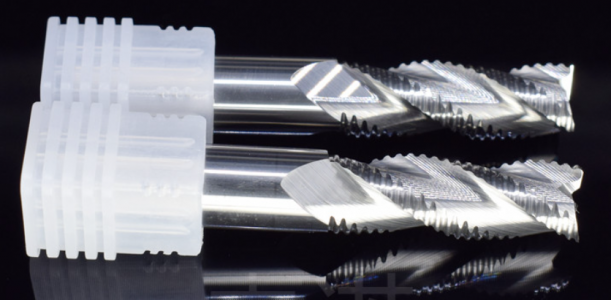

I have been using a 10 mm 2-flute coated carbide end mill for cutting aluminium and it does the job very well except for the relatively poor finish when doing side cutting. I don't blame it because the finish is mainly due to the rigidity of the machine ( the head shakes horizontally ). Recently I tried out a 3-flute , uncoated high helix end mill which is advertized to be great for cutting aluminium. The cutting edges are felt to be extremely sharp and the finish is better when doing shallow cuts. However, in deep cutting, the resistance to manual feed is clearly stronger indicating that the tool is not very effective in chewing up metal. Is that something expected for this kind of end mills ?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

High-helix end mills vs normal ones

- Thread starter compact8

- Start date

- Joined

- Nov 25, 2015

- Messages

- 9,779

so the more "THREADS" the faster the tool must turn to evacuate the same amount of material. It's like a coarse thread vs a fine thread. You need to make more turns of the screw to get it inI have been using a 10 mm 2-flute coated carbide end mill for cutting aluminium and it does the job very well except for the relatively poor finish when doing side cutting. I don't blame it because the finish is mainly due to the rigidity of the machine ( the head shakes horizontally ). Recently I tried out a 3-flute , uncoated high helix end mill which is advertized to be great for cutting aluminium. The cutting edges are felt to be extremely sharp and the finish is better when doing shallow cuts. However, in deep cutting, the resistance to manual feed is clearly stronger indicating that the tool is not very effective in chewing up metal. Is that something expected for this kind of end mills ?

with a fine.

So if turning faster, you can feed faster too. You should get a better finish, because you have more cuts per second, and that should level the piece a little better, making for a better finish with less scallops.

Also the tool will stay sharper longer because more cutting area is being used, and less is being taken by each point on the cutting edge. That relieves the amount of stress and impact on the edge.

That's my take on it... I am sure others will say I am wrong, or adjust what I have said...

- Joined

- Jan 31, 2016

- Messages

- 12,917

I've never liked them . I have a few larger mills used when we did deep pocket battery boxes ( aluminum ) . They seemed like they squealed more than regular end mills and didn't cut as freely as compact stated . I'm going off of memory and I might be completely wrong . Skip tooth roughing mills are the go-to these days for material removal .

- Joined

- Mar 26, 2018

- Messages

- 2,725

So you're changing a couple variables at a time. I've used 3 flute 37-45 degree "high" helix carbide endmills for aluminum on my CNC for years. Love them. Here are some thoughts.

- 3 Flute endmills are a nice mid ground between 2 flute (large chips, slow feedrate) and 4 flute (small chips, faster feedrate). There is nothing intrinsically special about them. I like them for aluminum.

- Aluminum specific high polish endmills (e.g. YG-1 AluPower) are extremely sharp and have polished flutes for machining aluminum, plastic, and other soft, non-abrasive, non-ferrous metals. The sharp edges reduce cutting forces (more MMR per HP) and the polished flutes help evacuate chips from gummy materials especially well (2000 series aluminum, copper, etc.). They often have a polished cutting land which gives excellent surface finish. Results are best with very high spindle speed (12,000 rpm for a 3/8" tool is recommended for the YG-1 AluPower endmills) and good flood coolant with fine particulate filtration.

- High helix endmills have the following benefits:

- High helix endmills (common for both aluminum endmill and endmills for finishing hard steels) are designed to transfer much of the cutting force from the radial to the axial direction. This reduces tool deflection and aligns the cutting forces with the stiffest part of the machine (the nod in the head/column).

- Better chip evacuation as the chips are pulled upwards strongly. This is more important in interior pockets and slots.

- Better part surface finish and reduced likelihood of chatter. The cutted can have multiple flutes engaged in the cut. This is a more stable cutting situation.

- High helix endmills generate a LOT of downwards axial cutting forces. This can lead to tool slippage in marginal tool holders.

- Joined

- Mar 26, 2018

- Messages

- 2,725

One additional comment. Just as the tool can be pulled downwards out of the holder, the tool also can pull the workpiece upwards. This is not an appropriate tool for marginally clamped workpieces, especially flat sheet materials or delicate overhangs on your part.

- Joined

- Jan 31, 2016

- Messages

- 12,917

I could tell you a story about that !One additional comment. Just as the tool can be pulled downwards out of the holder, the tool also can pull the workpiece upwards. This is not an appropriate tool for marginally clamped workpieces, especially flat sheet materials or delicate overhangs on your part.

- Joined

- Jan 31, 2016

- Messages

- 12,917

I missed this , but this was exactly what we were doing . Deep pockets in Nasa battery boxes .Better chip evacuation as the chips are pulled upwards strongly. This is more important in interior pockets and slots.

Lou went on to run the AMT lab down Martins after serving his apprenticeship . Great guy , but hard to believe .

Lou went on to run the AMT lab down Martins after serving his apprenticeship . Great guy , but hard to believe .... Results are best with very high spindle speed (12,000 rpm for a 3/8" tool is recommended for the YG-1 AluPower endmills) and good flood coolant with fine particulate filtration....

12K rpm is way outside the envelope of my manual mill which can do 2.2 K max. What I can't understand is with the cutting edges so sharp, why is it more effortful in biting metal compared with ordinary end mills when used on manual mills ?