- Joined

- Sep 16, 2014

- Messages

- 6

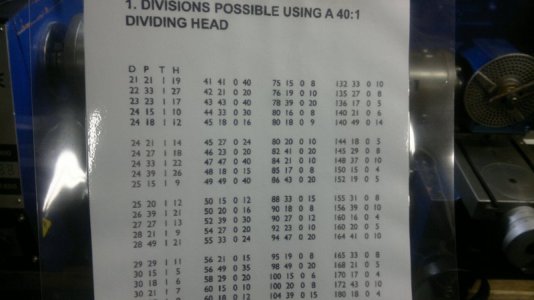

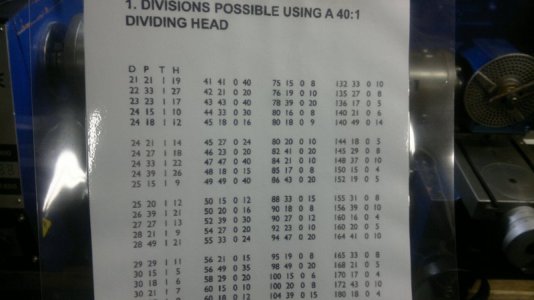

I hope you all will be patient with me,as I said I am actually a welder by trade and know(I hope) most of the basics, I can do a few things and have made a few parts namely:work accurately enough to make a few firearm silencers that work well,slave cylinder for my SOHC 750 honda,brake reservoir for brake master cylinder on said honda 750 so I can work accurately.my problem comes in with my dividing head,my maths is worse that very bad so I try to use fixed formuli that I can find.I have a book on dividing,(will post pics) and the chart shown in it do not match up with the holes in my dividing plate,or rather say there are no charts for the holes I have in my plate and I was wondering if there is a formula to work this out for a dope like me

.

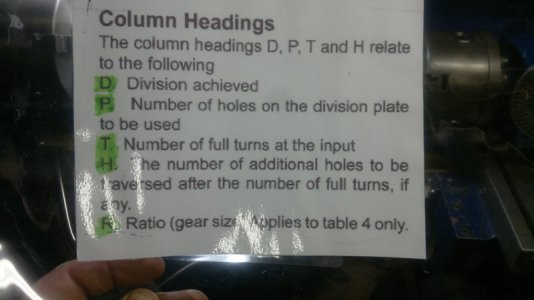

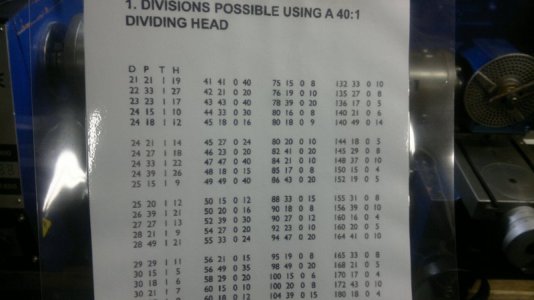

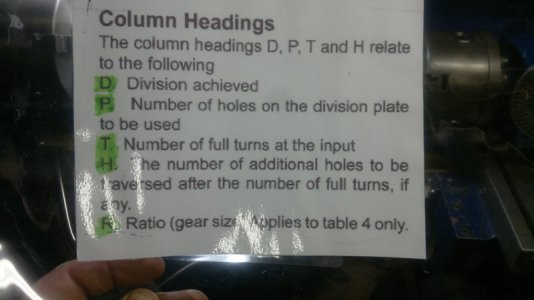

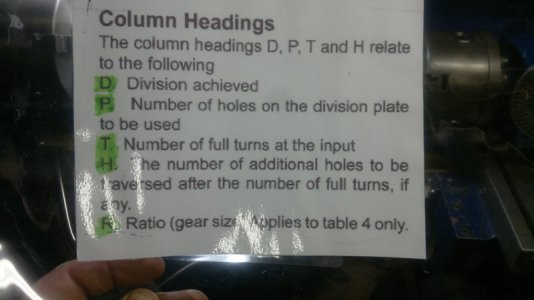

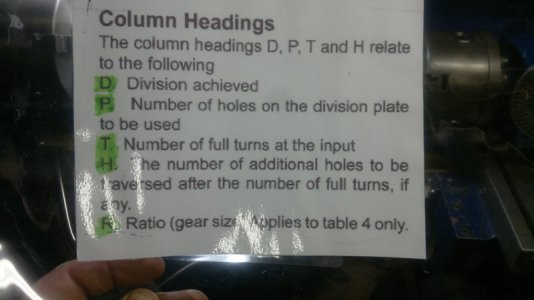

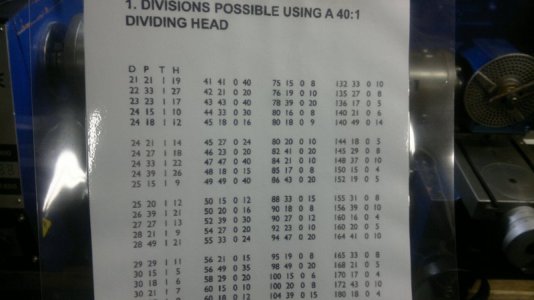

I'm looking at the highlighted "P" number of holes on the dividing plate to be used,not one of those holes in that column are on my plate so I need to know if that is a uncommon plate or am I just being an idiot and looking at the wrong thing,it is a 40:1 dividing head I have and I have made a chuck key for myself at(obviously) 10 turns per 1/4,let me know what other info anybody needs,sorry to seem so stupid but I probably am.PS: sorry the 37 row is there for 37 divisions and 148 divisions.

.

I'm looking at the highlighted "P" number of holes on the dividing plate to be used,not one of those holes in that column are on my plate so I need to know if that is a uncommon plate or am I just being an idiot and looking at the wrong thing,it is a 40:1 dividing head I have and I have made a chuck key for myself at(obviously) 10 turns per 1/4,let me know what other info anybody needs,sorry to seem so stupid but I probably am.PS: sorry the 37 row is there for 37 divisions and 148 divisions.

Last edited: