- Joined

- Jan 22, 2023

- Messages

- 80

Right now we have a black box version control unit in R&D. This will present a sealed motor and sealed air cooled control unit.

The control head is only 3" + 2 " and easy to place in a convenient location. I will post images as soon as it is finalized.

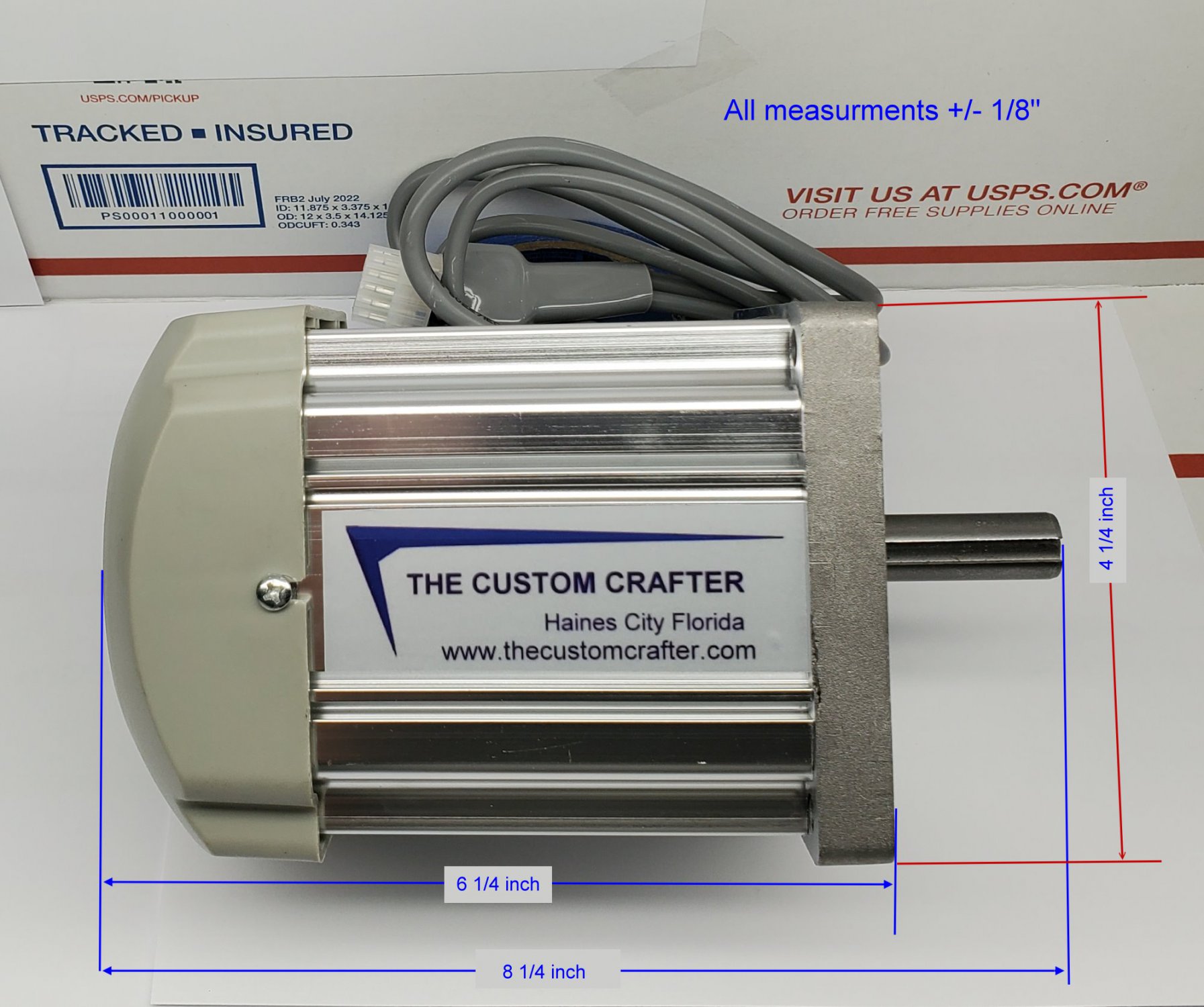

Until than check out the truly flat face and strait shaft BLDC 1500W motor we recently released.

This motor boasts 16 NM torque and a speed range of 300 to 3,500 RPM.

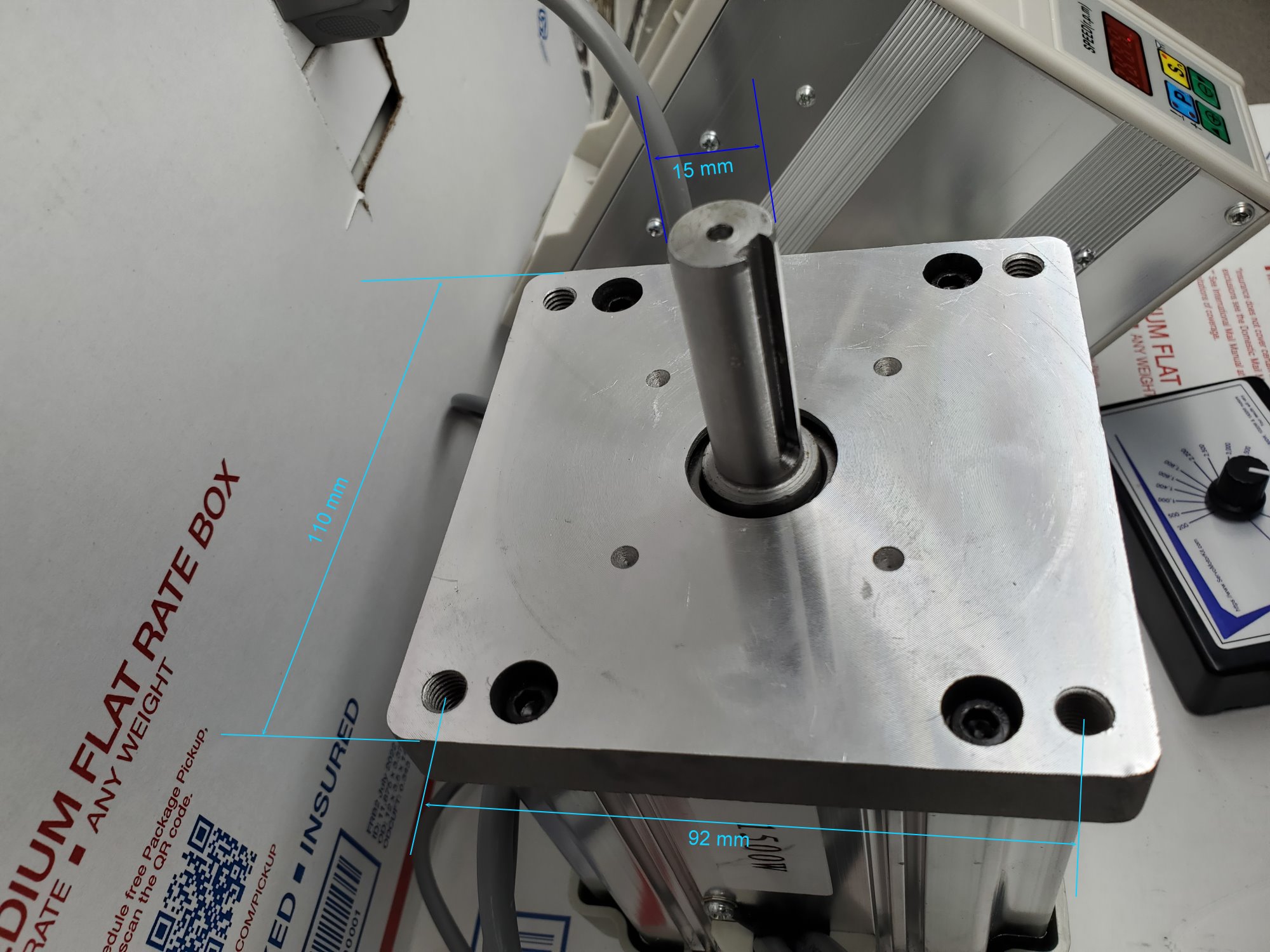

The flat face eases DIY fitting to your machine.

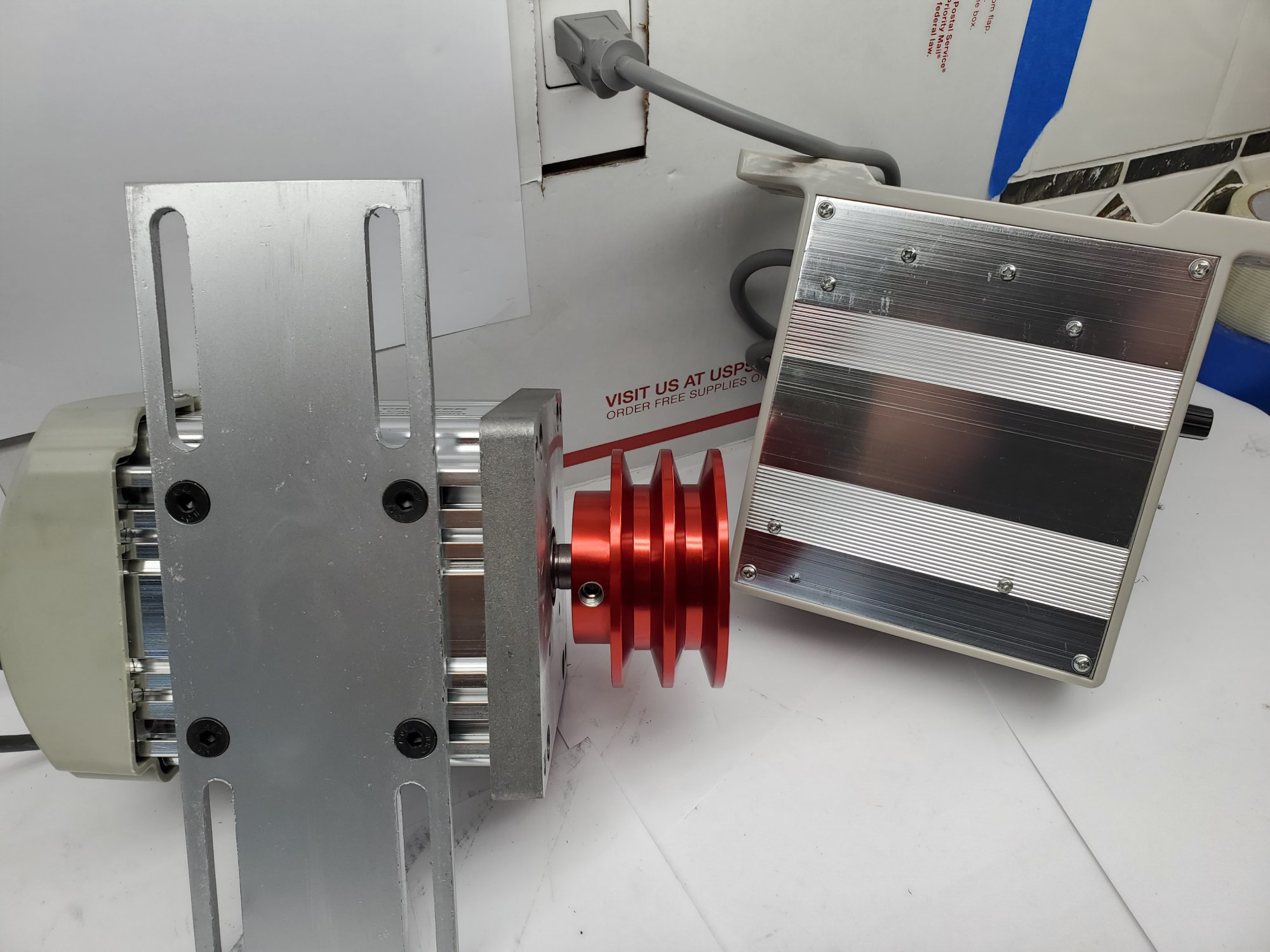

The strait shaft supports multi sheave pulleys.

The control head is only 3" + 2 " and easy to place in a convenient location. I will post images as soon as it is finalized.

Until than check out the truly flat face and strait shaft BLDC 1500W motor we recently released.

This motor boasts 16 NM torque and a speed range of 300 to 3,500 RPM.

The flat face eases DIY fitting to your machine.

The strait shaft supports multi sheave pulleys.