- Joined

- Feb 2, 2013

- Messages

- 3,957

Hello all,

i went and purchased a manual ring roller SKU# 36790 from harbor freight for right around 80 bucks

out of the box it seems like it is made solid enough.

one thing i found strange was the length of the crank arm, it is very long.

i'm assuming the length was chosen for women and children to have enough leverage to use the roller.

the crank arm also travels uncomfortably closely to the base unit

i found the length clumsy to use and unnecessary , so

i had to change that!

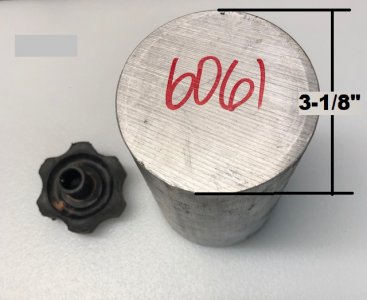

i took a hunk of 12L14,

1.5" x 3" and bored a 41/64" hole and cross drilled to .3125" for the stock roll pin and broke the edges and countersunk the holes.

i flipped over the work and cross drilled the billet to 1/2".

i rotated the work 90° and cross drilled again and tapped for 1/4-20tpi, this will retain the adjustable length crank arm.

i end drilled and tapped the 1/2" crank arm on one end to 1/4-20tpi for retention in the driven shaft with a bolt

i heated the new crank arm with the oxy/acetylene rig and bent the crank arm handle.

i created flats on the new adjustable crank arm to create a non slip lock

assembly was simple and took only a few minutes.

without further adieu, my ring roller mod!

top: OEM crank arm

bottom: adjustable crank arm

the roller works good in the present state, but there is one other mod i'm going to make!

stay tuned for more action and adventure!

i went and purchased a manual ring roller SKU# 36790 from harbor freight for right around 80 bucks

out of the box it seems like it is made solid enough.

one thing i found strange was the length of the crank arm, it is very long.

i'm assuming the length was chosen for women and children to have enough leverage to use the roller.

the crank arm also travels uncomfortably closely to the base unit

i found the length clumsy to use and unnecessary , so

i had to change that!

i took a hunk of 12L14,

1.5" x 3" and bored a 41/64" hole and cross drilled to .3125" for the stock roll pin and broke the edges and countersunk the holes.

i flipped over the work and cross drilled the billet to 1/2".

i rotated the work 90° and cross drilled again and tapped for 1/4-20tpi, this will retain the adjustable length crank arm.

i end drilled and tapped the 1/2" crank arm on one end to 1/4-20tpi for retention in the driven shaft with a bolt

i heated the new crank arm with the oxy/acetylene rig and bent the crank arm handle.

i created flats on the new adjustable crank arm to create a non slip lock

assembly was simple and took only a few minutes.

without further adieu, my ring roller mod!

top: OEM crank arm

bottom: adjustable crank arm

the roller works good in the present state, but there is one other mod i'm going to make!

stay tuned for more action and adventure!

Last edited:

)

)