I have learned that sometimes I just need to buy the good stuff. Like carbide endmills.

Other times the cheap stuff seems to do just fine for me.

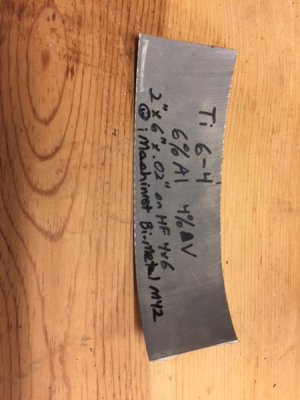

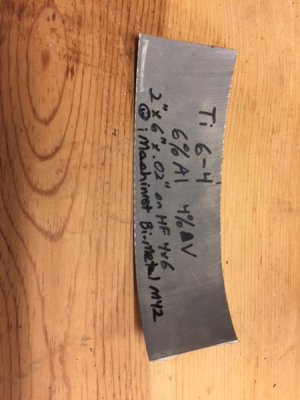

My cheap HF 4x6 bandsaw just did an impressive cut. With a good blade (imachinist M42 Bi-Metal), and with no special adjustment of the saw, it cut off a uniform .02" from a 2x6" piece of titanium. That stuff is way hard to cut--a normal HSS blade does not even scrape it. Took two hours with extra pressure.

There was ample opportunity to veer. It just stayed straight on course.

I probably am just having a lucky run with it--there are many adjustments folks write about for the saw. I have about 50 hours of cutting on it over the past year plus. Have not adjusted a thing yet.

(I didn't need the .02--I needed the block it came off of to be .08 smaller. With the .045 cut width I only had .015 more to do on the mill. With a max rate of .001 per layer and needing 5 passes per layer, it was faster to just set and forget the saw. (And those 15 layers took forever--the face mill cannot do Ti.))

-Bill

Other times the cheap stuff seems to do just fine for me.

My cheap HF 4x6 bandsaw just did an impressive cut. With a good blade (imachinist M42 Bi-Metal), and with no special adjustment of the saw, it cut off a uniform .02" from a 2x6" piece of titanium. That stuff is way hard to cut--a normal HSS blade does not even scrape it. Took two hours with extra pressure.

There was ample opportunity to veer. It just stayed straight on course.

I probably am just having a lucky run with it--there are many adjustments folks write about for the saw. I have about 50 hours of cutting on it over the past year plus. Have not adjusted a thing yet.

(I didn't need the .02--I needed the block it came off of to be .08 smaller. With the .045 cut width I only had .015 more to do on the mill. With a max rate of .001 per layer and needing 5 passes per layer, it was faster to just set and forget the saw. (And those 15 layers took forever--the face mill cannot do Ti.))

-Bill