- Joined

- Nov 28, 2016

- Messages

- 2,793

You could say I'm nuts... my wife would agree with you...

A few weeks ago, we drove up to Tuckahoe Steam and Gas in Easton, Maryland and brought home another Hendey 14x6 lathe. This is the lathe that @DiscoDan had advertised way back in June, I think... it belonged to a friend of his that passed away earlier in the year.

Now that my Hendey refurbish #2 is winding down, (I'm not finished with it, but have started planning to get started on #3 in a few weeks), I've decided to give a rundown on #3, the good, the bad, and the ugly...

To start with, I'll provide a little history on this machine.

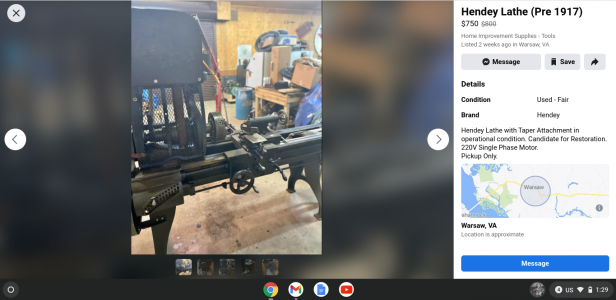

It was manufactured in 1918, and sold to Frankford Arsenal in Philadelphia... but was originally an 8 speed geared head lathe with a motor drive. In 1938, it was shipped back to Hendey for an overhaul, at which time it was converted to a conehead lathe and fitted with 'cabinet style' legs. A motor/ countershaft belt driven system was also added. So, it is a 1918 lathe with a 1938 headstock and drive system.

We picked the lathe up in Maryland and drove home, 5 hours of the 12 hour drive was in a pouring rain, so as soon as we got home, I immediately disassembled the lathe so it would thoroughly dry out and not have any uncureable rust established.

The legs and chip pan are in good condition, with just a good cleaning and painting needed. The bed and ways are also decent, with minor noticeable wear on the ways, some surface rust, but nothing that worries me too much.

The headstock is also in good condition, no broken teeth on any of the gears, and the spindle and spindle bearings are in excellent condition. The feed reversing gears are in better condition than either of my other Hendeys, from what I can tell just looking at them. The back gears are also good.

The carriage has some surface rust, nothing serious, the compound has had the t-slot broken out and repaired at some point... it may need some attention, we'll see.

The apron assembly is all in good condition, except both feed clutch knobs are missing... one was replaced with a star knob, the other with an aluminum hand wheel...

I will machine new original-style knobs to replace them.

The tailstock is in very good condition, the quill screw has been lengthened, but should work fine... if not, I'll replace it.

The real challenge will be in getting the taper attachment working... it is missing some pieces, and other pieces are broken. The upper slotted clamp is badly broken...

That will be challenging to repair... also the lower clamp bar that connects the cross slide screw to the TA is broken...

...right where the pivot goes through it. I don't know if it would be better to attempt to repair this bar, or machine a whole new piece.

The taper attachment is missing the angle adjustment knob, both of the end plates, the swivel block gib, and the clamp that clamps to the bed way. The knob, plates, and gib I can machine replacements, but the clamp is going to be... difficult....

This is the clamp on #2...

I like a good challenge, though... so I'll try...

Sorry about the long post... I'll get started on #3 in a few weeks and keep this updated as I go.

-Bear

A few weeks ago, we drove up to Tuckahoe Steam and Gas in Easton, Maryland and brought home another Hendey 14x6 lathe. This is the lathe that @DiscoDan had advertised way back in June, I think... it belonged to a friend of his that passed away earlier in the year.

Now that my Hendey refurbish #2 is winding down, (I'm not finished with it, but have started planning to get started on #3 in a few weeks), I've decided to give a rundown on #3, the good, the bad, and the ugly...

To start with, I'll provide a little history on this machine.

It was manufactured in 1918, and sold to Frankford Arsenal in Philadelphia... but was originally an 8 speed geared head lathe with a motor drive. In 1938, it was shipped back to Hendey for an overhaul, at which time it was converted to a conehead lathe and fitted with 'cabinet style' legs. A motor/ countershaft belt driven system was also added. So, it is a 1918 lathe with a 1938 headstock and drive system.

We picked the lathe up in Maryland and drove home, 5 hours of the 12 hour drive was in a pouring rain, so as soon as we got home, I immediately disassembled the lathe so it would thoroughly dry out and not have any uncureable rust established.

The legs and chip pan are in good condition, with just a good cleaning and painting needed. The bed and ways are also decent, with minor noticeable wear on the ways, some surface rust, but nothing that worries me too much.

The headstock is also in good condition, no broken teeth on any of the gears, and the spindle and spindle bearings are in excellent condition. The feed reversing gears are in better condition than either of my other Hendeys, from what I can tell just looking at them. The back gears are also good.

The carriage has some surface rust, nothing serious, the compound has had the t-slot broken out and repaired at some point... it may need some attention, we'll see.

The apron assembly is all in good condition, except both feed clutch knobs are missing... one was replaced with a star knob, the other with an aluminum hand wheel...

I will machine new original-style knobs to replace them.

The tailstock is in very good condition, the quill screw has been lengthened, but should work fine... if not, I'll replace it.

The real challenge will be in getting the taper attachment working... it is missing some pieces, and other pieces are broken. The upper slotted clamp is badly broken...

That will be challenging to repair... also the lower clamp bar that connects the cross slide screw to the TA is broken...

...right where the pivot goes through it. I don't know if it would be better to attempt to repair this bar, or machine a whole new piece.

The taper attachment is missing the angle adjustment knob, both of the end plates, the swivel block gib, and the clamp that clamps to the bed way. The knob, plates, and gib I can machine replacements, but the clamp is going to be... difficult....

This is the clamp on #2...

I like a good challenge, though... so I'll try...

Sorry about the long post... I'll get started on #3 in a few weeks and keep this updated as I go.

-Bear