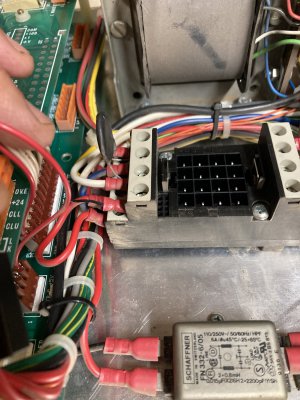

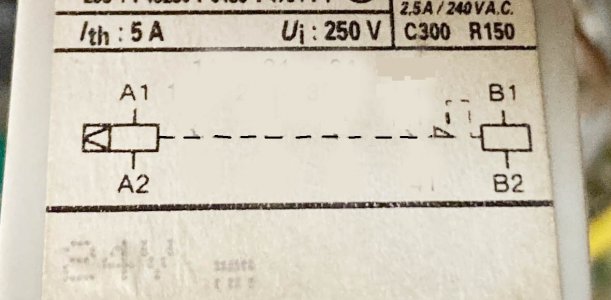

I have a old Boxford cnc lathe that I'm trying to get up and running. It will not power the spindle motor in forward, reverse works as it should. When I push the either direction button on the console I hear and see the relay flipping. I don't have a schematic and trying to understand the relay schematic. The diagram looks like there should be 3 banks of terminals ( 1 for the constant and 2 for the variable side) but it looks like there are 4 banks of terminals. I'm missing something, can anyone help? I don't have a schematic and the relay in question is a RHK412B if that helps.

-Brad

-Brad