I can not deciepher the threading chart on this lathe. To cut 16 threads it looks like the gearbox would be ACR1 but that isn't correct. The manual os pretty pour on this. It says all inch gears can me cut With the 30 tooth on top and the 60 on the bottom. I think with a 60 on top and bottom it would be correct but my machine didn't come with two 60's.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help Threading on a PM -1440BV

- Thread starter R Clark

- Start date

- Joined

- Apr 30, 2015

- Messages

- 12,192

Sounds like it was shipped with one gear missing- I think a call to PM is in order

@R Clark

Lots of confusion here about this lathe. The PM front page description says that the Leadscrew is 10TPI, but the manual says it is the more common 8TPI (page 7, specifications). Perhaps the 10TPI was referring to the x-feed lead screw? The manual does not shed a lot of light on how the gear box, nor the saddle gearing, is built.

Looks like the PM1440BV is Chinese made. Its gear box is "somewhat" similar to that of the Taiwan made PM1440GT, which I purchased, but not the same.

By the way, one of my gears was also missing, but with a call to PM they sent it to me. Not an issue!

I constructed, and have provided to HM, an extensive Excel workbook to predict all of the possible Threads and feed rates for all possible gears in all possible positions for a few different lathes. Inside this workbook are several worksheets for various lathes. But it is also set up so that you can just copy one of these onto a new sheet and then set it up the specific parameters for other lathes and it will work. In the worksheet you can select knob/handle gears for various positions and select external gears via drop down choices and it then provides the TPI and various other calculations.

So looking at the manual and table for the PM1440BV we see that the A-B, C-D knobs are just factors of 2x. This is the same as the PM1440GT. The right lower knob has 4 positions as does the PM1440GT, but are labeled via RSTU rather than WXYZ letters of the GT. The top knob also has 1-4 thread positions plus Feed position 0. Again "similar" to the GT, but the GT uses PQRIT where I is the Feed position. However, I don't think the ratios are a match between GT's lever and the BV's knob positions.

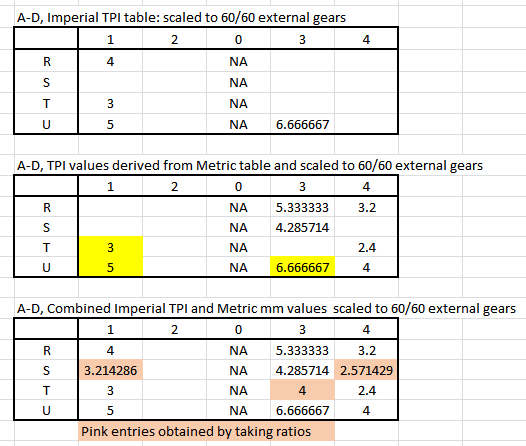

Looking at the Imperial Threading table you posted we see that they only provide gear positions: R1, T1, U1, and U3. One has to ask what happens when one uses S or the other numbered positions. Lots missing. This is not uncommon, but usually more info is provided allowing one to derived the other positions gear ratios. The metric table provides a few others, but 3 of them are the same knob settings with different external gears. One can back out the external gears from the tables to yield gear box ratios. I did this and the results are shown below.

I have laid out the TPI values for various knob setting when A-D knobs are chosen. I used both the Imperial table and the metric table and the results are shown when the external gears are set to be 60/60. If one wanted to use the 30/60 all of the values just change by a factor of 2. The ones highlighted in yellow are the common gear combination between Imperial and metric tables and so these yellow entries in the metric table adds nothing to the TPI table . Lastly, there is a similar table where the metric and imperial are combined and the Pink entries are computed by using the ratios of the values in the table. The combined tables had no entries in the "2" column so these missing entries cannot be filled in. If you could accurately measure scratch threads using A-D, 60/60 or 60/30 external gears, and each of the R-2, S-2, T-2, and U-2 then we check them for consistency and determine the "2" column values. Then you would have a complete description of the gear box settings.

By the way, you can quickly check three entries in the table below: A-D, 60/60, R1, T3, and U4 knob settings should all give the same TPI value, 4.

Ideally you might be able to look at the feed tables and figure some of it out if you can figure out the gearing in the saddle, but .... it is not uncommon that the Feed tables are inaccurate and sometimes just wrong.

Lastly, I tried my hand at comparing the feed ratios to the TPI ratios I put into the attached combined table. I found that the feed values for the gear setting T and R feed rows were in agreement with the TPI table, but the S and U rows were not. I do not know what to make of this except to say that I have found other feed tables on other lathes to be off. I did the same for the x-feed table and the results were similar, T and R rows in the feed table seem to be consistent with the TPI table, but the S and U rows were not.

You can find a copy of the Excel Workbook at:

Dave L.

So what did you get for a TPI value when you used the AC-R1 knob settings? Was it off by just a factor of 2x or was it something more strange?I can not deciepher the threading chart on this lathe. To cut 16 threads it looks like the gearbox would be ACR1 but that isn't correct.

Lots of confusion here about this lathe. The PM front page description says that the Leadscrew is 10TPI, but the manual says it is the more common 8TPI (page 7, specifications). Perhaps the 10TPI was referring to the x-feed lead screw? The manual does not shed a lot of light on how the gear box, nor the saddle gearing, is built.

Looks like the PM1440BV is Chinese made. Its gear box is "somewhat" similar to that of the Taiwan made PM1440GT, which I purchased, but not the same.

By the way, one of my gears was also missing, but with a call to PM they sent it to me. Not an issue!

I constructed, and have provided to HM, an extensive Excel workbook to predict all of the possible Threads and feed rates for all possible gears in all possible positions for a few different lathes. Inside this workbook are several worksheets for various lathes. But it is also set up so that you can just copy one of these onto a new sheet and then set it up the specific parameters for other lathes and it will work. In the worksheet you can select knob/handle gears for various positions and select external gears via drop down choices and it then provides the TPI and various other calculations.

So looking at the manual and table for the PM1440BV we see that the A-B, C-D knobs are just factors of 2x. This is the same as the PM1440GT. The right lower knob has 4 positions as does the PM1440GT, but are labeled via RSTU rather than WXYZ letters of the GT. The top knob also has 1-4 thread positions plus Feed position 0. Again "similar" to the GT, but the GT uses PQRIT where I is the Feed position. However, I don't think the ratios are a match between GT's lever and the BV's knob positions.

Looking at the Imperial Threading table you posted we see that they only provide gear positions: R1, T1, U1, and U3. One has to ask what happens when one uses S or the other numbered positions. Lots missing. This is not uncommon, but usually more info is provided allowing one to derived the other positions gear ratios. The metric table provides a few others, but 3 of them are the same knob settings with different external gears. One can back out the external gears from the tables to yield gear box ratios. I did this and the results are shown below.

I have laid out the TPI values for various knob setting when A-D knobs are chosen. I used both the Imperial table and the metric table and the results are shown when the external gears are set to be 60/60. If one wanted to use the 30/60 all of the values just change by a factor of 2. The ones highlighted in yellow are the common gear combination between Imperial and metric tables and so these yellow entries in the metric table adds nothing to the TPI table . Lastly, there is a similar table where the metric and imperial are combined and the Pink entries are computed by using the ratios of the values in the table. The combined tables had no entries in the "2" column so these missing entries cannot be filled in. If you could accurately measure scratch threads using A-D, 60/60 or 60/30 external gears, and each of the R-2, S-2, T-2, and U-2 then we check them for consistency and determine the "2" column values. Then you would have a complete description of the gear box settings.

By the way, you can quickly check three entries in the table below: A-D, 60/60, R1, T3, and U4 knob settings should all give the same TPI value, 4.

Ideally you might be able to look at the feed tables and figure some of it out if you can figure out the gearing in the saddle, but .... it is not uncommon that the Feed tables are inaccurate and sometimes just wrong.

Lastly, I tried my hand at comparing the feed ratios to the TPI ratios I put into the attached combined table. I found that the feed values for the gear setting T and R feed rows were in agreement with the TPI table, but the S and U rows were not. I do not know what to make of this except to say that I have found other feed tables on other lathes to be off. I did the same for the x-feed table and the results were similar, T and R rows in the feed table seem to be consistent with the TPI table, but the S and U rows were not.

You can find a copy of the Excel Workbook at:

or a more recent version with drafts versions of sheets for a couple of other lathe that folks were using... located at:TPI Feeds X-Feeds: Generalized Excel file for your Lathe

I edited the PM1440HD-draft worksheet

Dave L.