Hi All,

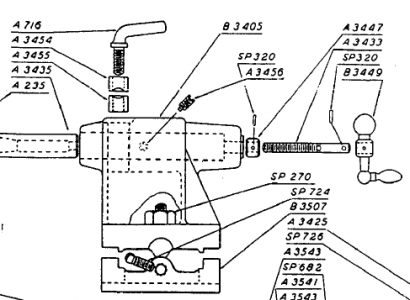

This is my first post. I recently acquired a Sears 109 mini lathe and am currently in the process of performing a full restoration. Once challenge I"m facing is hos to separate the handle from the tailstock assembly. There appears to be a recessed pin of some sort but I can't tell if it's threaded or simply a friction fit. I tried tapping with a punch and it didn't budge. I don't want to be too aggressive in case it is threaded and risk damaging the threads. Has anyone done this before? Would appreciate any advice or guidance.

This is my first post. I recently acquired a Sears 109 mini lathe and am currently in the process of performing a full restoration. Once challenge I"m facing is hos to separate the handle from the tailstock assembly. There appears to be a recessed pin of some sort but I can't tell if it's threaded or simply a friction fit. I tried tapping with a punch and it didn't budge. I don't want to be too aggressive in case it is threaded and risk damaging the threads. Has anyone done this before? Would appreciate any advice or guidance.