I just began a full tear-down and restoration of a (new to me) Mori Seiki MS850 built in 1977-8. I'm brand new to machining, and this is my first resto project.

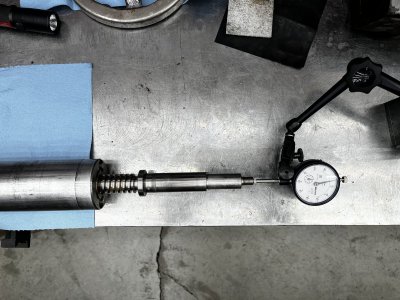

As I go along, I'm marking some parts for purchase brand new: Whacheon told me they sell every single part for the MS850 except the lead screw. That's good news, bringing me to the issue: I need help to assess whether the tailstock ram/quill's brass nut should be replaced. In my enthusiasm to disassemble, I forgot to measure backlash, but I did confirm butter-smooth ram movement before disassembly. The steel ram screw at all depths in the brass nut wiggles very slightly side-to-side, and I can push-pull the screw longitudinally a few thou (using my handcrometer ). Is this amount of play a concern? Should the screw be tight instead? Does the play justify brass nut replacement? Now would be the time. I just don't know whether the amount of play is concerning when I would use the ram unlocked.

). Is this amount of play a concern? Should the screw be tight instead? Does the play justify brass nut replacement? Now would be the time. I just don't know whether the amount of play is concerning when I would use the ram unlocked.

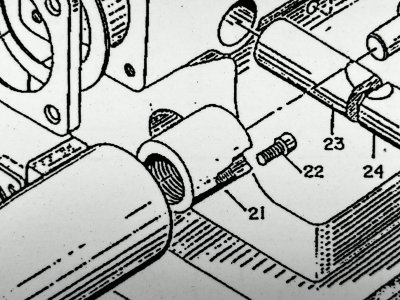

The attached pictures show that the brass nut (part 21 in the parts diagram but stamped "15" in my picture) is likely pressed into the ram/quill and held in place by two screws (part 22). I do not have a working lathe, nor do I have a shop press or mill. A friend has a press.

As I go along, I'm marking some parts for purchase brand new: Whacheon told me they sell every single part for the MS850 except the lead screw. That's good news, bringing me to the issue: I need help to assess whether the tailstock ram/quill's brass nut should be replaced. In my enthusiasm to disassemble, I forgot to measure backlash, but I did confirm butter-smooth ram movement before disassembly. The steel ram screw at all depths in the brass nut wiggles very slightly side-to-side, and I can push-pull the screw longitudinally a few thou (using my handcrometer

). Is this amount of play a concern? Should the screw be tight instead? Does the play justify brass nut replacement? Now would be the time. I just don't know whether the amount of play is concerning when I would use the ram unlocked.

). Is this amount of play a concern? Should the screw be tight instead? Does the play justify brass nut replacement? Now would be the time. I just don't know whether the amount of play is concerning when I would use the ram unlocked.The attached pictures show that the brass nut (part 21 in the parts diagram but stamped "15" in my picture) is likely pressed into the ram/quill and held in place by two screws (part 22). I do not have a working lathe, nor do I have a shop press or mill. A friend has a press.