- Joined

- Dec 6, 2021

- Messages

- 235

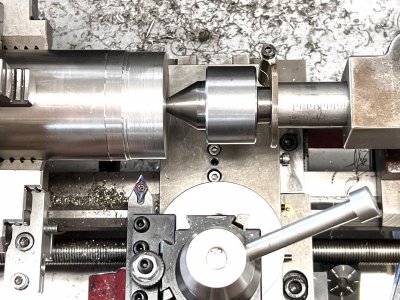

I'm pretty new at this stuff. But I've been happy with the results I've gotten turning 304SS in sizes under an inch. So I felt emboldened So when I found a 4' length of 303 round bar at the local scrap yard... But the larger diameter (even in a more machinable alloy) is not nearly as cooperative. So I'm asking for help...

I would appreciate input on how to approach this and improve/optimize my cut. I also need a good starting point from which to test ideas. With little experience, I lack instincts about which variables to test/change first. Feeds, speeds and DOC are the easiest changes to try. But without knowing if I'm starting with the 'right' tool/geometry, it's hard to know if I'm just spinning my wheels...

The setup/modifications:

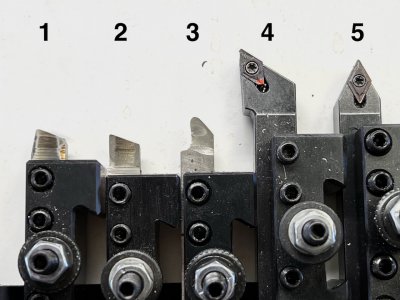

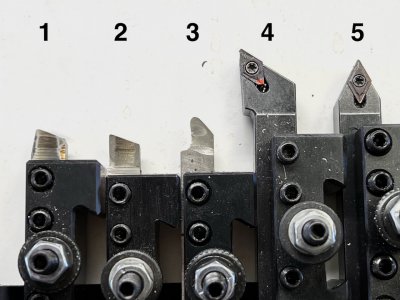

Cutters 1 & 2 seem to have more good finish potential, but with so little power they are prone to chatter or stopping the spindle at anything close to a productive cut. They do "okay" in low gear between 250-290RPM, but hand feeding with .0015-20" DOC is like watching corn grow.

TLDR:

I would appreciate input on how to approach this and improve/optimize my cut. I also need a good starting point from which to test ideas. With little experience, I lack instincts about which variables to test/change first. Feeds, speeds and DOC are the easiest changes to try. But without knowing if I'm starting with the 'right' tool/geometry, it's hard to know if I'm just spinning my wheels...

The setup/modifications:

- HF/Seig C2/3 with OEM 250w motor (for now)

- 3:1 underdrive pulley kit for extra torque

- "tuned" brass saddle clamp plates

- "tuned" cross slide ways & gib

- solid toolpost block (compound slide eliminator)

Cutters 1 & 2 seem to have more good finish potential, but with so little power they are prone to chatter or stopping the spindle at anything close to a productive cut. They do "okay" in low gear between 250-290RPM, but hand feeding with .0015-20" DOC is like watching corn grow.

TLDR:

- Should I be looking at ground DMCT bits for aluminum that some have said would well on underpowered machines? If so, do you have a specific recommendation? (I get a little overwhelmed by the zillions of insert choices...)

- Are their "off the menu" HSS tool grinds better suited to low-power machines? The recommended geometry for steel and SS in the Engineers Black Book seem like they are better suited to bigger machines than mine...