- Joined

- Dec 20, 2012

- Messages

- 9,422

There have been a few threads where guys ask about HSS tooling and how to grind them to account for the helix angles of a thread. The most recent one is here and I chose to open a new thread so as not to encroach on it: http://www.hobby-machinist.com/threads/threading-tool-helix-angle.58802/#post-484610

Note that I am not talking about inserted carbide threading tools with adjustable anvils to alter the helix angle/approach angle of the insert. I am referring to HSS threading tools for screwcutting on the lathe.

So, as a means to open the discussion, let me lead off with some questions that a hobby guy might have:

Note that I am not talking about inserted carbide threading tools with adjustable anvils to alter the helix angle/approach angle of the insert. I am referring to HSS threading tools for screwcutting on the lathe.

So, as a means to open the discussion, let me lead off with some questions that a hobby guy might have:

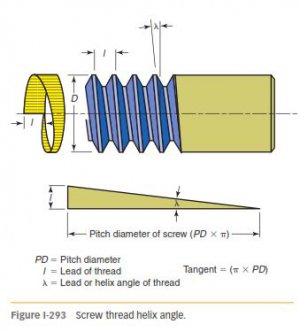

- what is this helix angle you're referring to? Can you measure it accurately and if so, how?

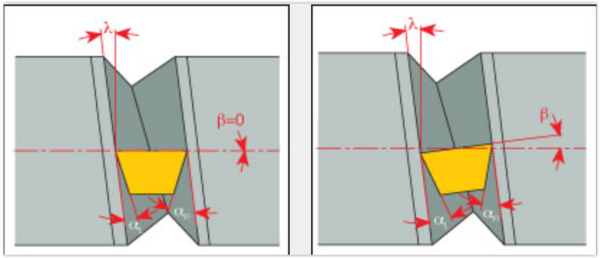

- assuming you can accurately measure it, how do you grind a HSS tool to account for the helix angle of a given thread, and do you need a different threading tool for each helix angle or group of helix angles?

- for the vast majority of threads we cut in a hobby shop, does trying to account for the helix angle of a thread make a demonstrable difference? I am not talking about Acme threads or large square threads here, just maybe up to 3/4 UNC or UNF or so.

- For these common threads, what role do the relief angles on the tool play? It is a given that the helix angle of a thread and the relief angles on a threading tool are totally different things.

- Does your tool holder that holds the turning tool on your QCTP allow you to alter the horizontal tilt or angle of your tool? If so, please show us a pic.

- Should I even bother about helix angles? Millions upon millions of threads have been cut with a standard HSS lathe tool so why change that?