- Joined

- Apr 8, 2013

- Messages

- 2,016

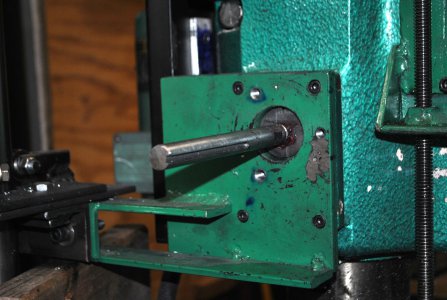

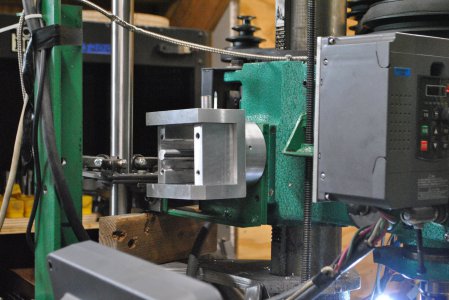

Arthritis and the hand crank on my mill don't get along. I had made a temporary powerlift (3 years ago, Ha) using a leadscrew that worked well ( a little too fast) but it had one drawback. If the leadscrew ever fatigued and broke the head would come crashing down. My permanent solution is a worm drive gearbox. I didn't have any plans so I made the gears and then built the gear box around them. My design was dependent on the stock I have, the equipment I have, and the experience that I don't have. I'm a retired building contractor so I had a powerful 500 rpm paddle drill laying around and it made a suitable motor for the gearbox. A bit crude but the finished product works great and the 30 to 1 ratio goes just the right speed for my purpose.

Attachments

-

fbDSC_3011.JPG464.9 KB · Views: 29

fbDSC_3011.JPG464.9 KB · Views: 29 -

fbDSC_3040.JPG528.9 KB · Views: 28

fbDSC_3040.JPG528.9 KB · Views: 28 -

fbDSC_3041.JPG315.1 KB · Views: 26

fbDSC_3041.JPG315.1 KB · Views: 26 -

fbDSC_3043.JPG500.2 KB · Views: 20

fbDSC_3043.JPG500.2 KB · Views: 20 -

fbDSC_3044.JPG398.4 KB · Views: 22

fbDSC_3044.JPG398.4 KB · Views: 22 -

fbDSC_3050.JPG592.6 KB · Views: 30

fbDSC_3050.JPG592.6 KB · Views: 30 -

fbDSC_3051.JPG398.8 KB · Views: 31

fbDSC_3051.JPG398.8 KB · Views: 31 -

fbDSC_3059.JPG436.6 KB · Views: 31

fbDSC_3059.JPG436.6 KB · Views: 31 -

fbDSC_3061.JPG474.5 KB · Views: 30

fbDSC_3061.JPG474.5 KB · Views: 30