- Joined

- Jul 2, 2014

- Messages

- 7,594

Today I finished making a hand wheel 5C collet closer for my Kent KLS-1340a. The photo above shows all the parts mocked up before they were finished. The hand wheel is made from a remnant sheave for a sailplane winch we built. The bearing holes were slightly too large for a press fit , so it went into my "scrap" until using it here. I really do not scrap anything. All the parts for this project were chosen from stuff already on hand except for the draw bar tube and the needle thrust bearing set. The entire design was based on what I had on hand.

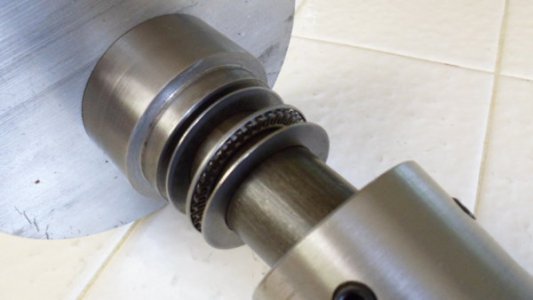

Needle thrust bearing, makes tightening and loosening the collet far easier. Also note the saw cut on the back side of the handle blank.

Silver solder job done by H-M member Talvare. Thanks, Ted! I do not have oxy-acetylene tanks. The fit was quite snug between the flange and the tube before silver soldering them. It was a light tap fit. Nonetheless, there was .031" of axial runout after it cooled, and a little radial runout as well, so it had to be machined further in the steady rest. It never got too hot, either...

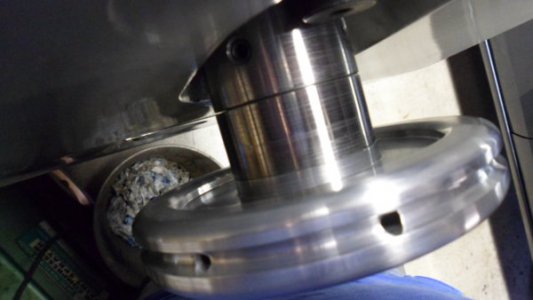

Cutting on the sheave/hand wheel. H-M member Talvare making the cuts on his older CNC Bridgeport mill. Thanks again, Ted! The part not being parallel because of the saw cut back made problems, some of which we were able to fix on the mill, and others that I had to do on my lathe, some in the steady rest and some while mounted in working position. I used about every technique I know and made up some new ones to get all the faces, radii, and O.D. back running true. Took most of a day. Next time I will be more careful to make sure my stock is flat and parallel, and I knew better anyway.

Looks pretty good to me after fussing with it, and it all now runs true within .002" at the O.D., radially, axially, and in swash plate mode. There is no sign it was so bad earlier.

The mystery metal those collar/bushing/spacer things are made of was impossible to get a surface finish I could be proud of. The lathe did not leave a good finish and trying to get the scratches out afterwards just made more scratches. I was careful about technique in polishing it out and used good files and abrasives, but still no better. (?)

It is really nice to finally have a collet closer. This is a lot easier than a three or four jaw, and a lot more accurate a lot quicker as well.

Another look at the scratches. This adapter is mounted to the spindle end by friction only, with four brass 1/8" straight thread pipe plugs (as used on lighting fixtures.) If the adapter ever spins it will not hurt the spindle. The four steel SHCS are an outboard spider that I incorporated into the design, only added 5/8" of axial length to the part, and none overall, because the hand wheel hub was also made longer intentionally to get more space for my hand between gear cover and hand wheel. I still need to make some brass tipped SHCS of varying lengths to use there.

Breakdown

5C collet mounting threads.

Finished hand wheel. Plenty of hand work in getting it to run true and look nice at the same time.

I drilled radial holes in the O.D. of the hand wheel for manually barring the hand wheel should it ever get stuck or if it needs to be tighter than by hand alone. The tool is just an old Phillips screwdriver that the business end was chowdered beyond repair. I cut the tip off and rounded the ends a bit to enter the holes easier. Between the foot brake and the barring tool, I should have no trouble loosening it should it get too tight for any reason.

It was an interesting project. I never put anything down on paper except a few numbers I was trying to hit while I was cutting a part. There are quite a few things that need to be taken into account because a lot of things are interacting. I am fortunate they all worked out well, no design issues at all so far. I think I will be happy with it.

Last edited: