- Joined

- May 26, 2017

- Messages

- 21

My buddy went to a sale and picked up 7 Stepper? motors and some other stuff for $40. They look like they have internal encoders and controllers. I was thrilled to pay him for the treasures as they looked promising. Per usual, they were not stored well. I think they were put in a coffee can and shaken once a month. Let's say no attempt to preserve them or protect them from moisture.

Off to the internet to see what we can learn.

The company that made them, Intelligent Motion Systems, is no longer viable and has been bought out twice from what I can tell.

Built-in controllers made them special.

The motors are designed for Windows XP

The Windows XP software site is no longer active.

Newer software may work for a newer version of this motor/servo/stepper.

The motors are sealed? - that is good if true.

They use step and direction for inputs - Widely believed to be true but only one version does.

Models include

Options include

Three Rotary Motor Lengths Available

I break down my model number: MDI1FRL23C7-EQ

An older motor

Does not use Step and Direction

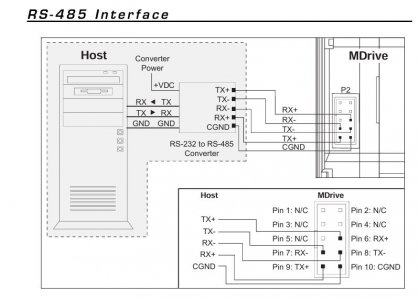

Uses an archaic terminal program utilizing RS422/485

Not interfaceable with Mach3 or other software (that I can find)

That was fun but no joy. There is no gold in this pan! All bad news? No, lots of parts, switches, bearings and stuff that will likely be useful, well worth the $40.

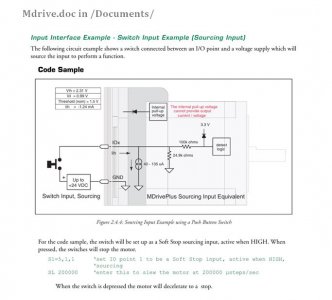

My one unanswered question is this: All the motors are using 3 wires to power and control. There is positive voltage in, a ground and a single I/O line. If anyone knows what this represents, let me know. RS485 has two data lines and when you add that to the required positive and negative power lines, I come up with four wires minimum, unless they are using the ground as a data line.

My goal is to get at least one thread on this website that talks about MDrive motors.

Off to the internet to see what we can learn.

The company that made them, Intelligent Motion Systems, is no longer viable and has been bought out twice from what I can tell.

Built-in controllers made them special.

The motors are designed for Windows XP

The Windows XP software site is no longer active.

Newer software may work for a newer version of this motor/servo/stepper.

The motors are sealed? - that is good if true.

They use step and direction for inputs - Widely believed to be true but only one version does.

- Step and direction

- RS422 or RS485

- SPI

- ModBus

- Ethernet

- CANopen

Models include

- Mdrive Plus

- Mdrive Plus2

- Mdrive Plus-65 - this is the sealed version

Options include

- Internal Magnetic Encoder for Closed Loop Control

- Integrated Planetary Gearbox

- Control Knob for Manual Positioning

- Linear Slide

Three Rotary Motor Lengths Available

I break down my model number: MDI1FRL23C7-EQ

- MD Mdrive

- I Version: Intelligent controller RS422-485

- 1 Input: Standard input

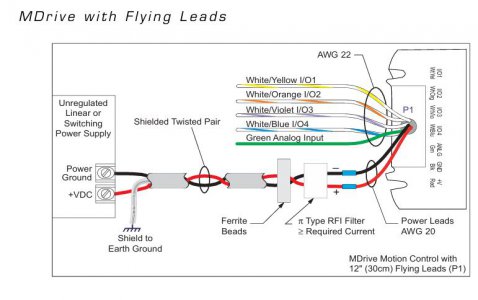

- F P1 connector: Flying leads

- R Protocol: RS422-485

- L P2 Connector: Wire Crimp

- 23 Size: Nema23

- C Motor Length: Triple stack

- 7 Voltage: 12-73v

- EQ Options: Internal magnetic encoder with 512 Lines

An older motor

Does not use Step and Direction

Uses an archaic terminal program utilizing RS422/485

Not interfaceable with Mach3 or other software (that I can find)

That was fun but no joy. There is no gold in this pan! All bad news? No, lots of parts, switches, bearings and stuff that will likely be useful, well worth the $40.

My one unanswered question is this: All the motors are using 3 wires to power and control. There is positive voltage in, a ground and a single I/O line. If anyone knows what this represents, let me know. RS485 has two data lines and when you add that to the required positive and negative power lines, I come up with four wires minimum, unless they are using the ground as a data line.

My goal is to get at least one thread on this website that talks about MDrive motors.

Attachments

Last edited: