- Joined

- Nov 23, 2014

- Messages

- 2,634

Been awhile since I’ve posted a reproduction Erector set part thread. Here’s one that took quite a bit of time and involved a number of different parts that go into an assembly: circa 1913 Erector set motor. Here are a few pictures of the finished product.

Reproduction assembled 1913 Erector set motor

And it runs on 6V!

First, the obligatory history lesson. . . A.C. Gilbert introduced the Erector set in 1913. The sets came in various sizes numbering from No. 0 up through No. 8. Sets No. 4 – No. 8 included a “kit” to build an electric motor. The construction was a bit involved, so the factory offered to assemble the motor for $0.50 if the child sent the parts back to the New Haven factory.

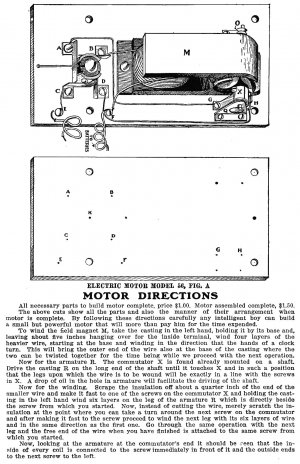

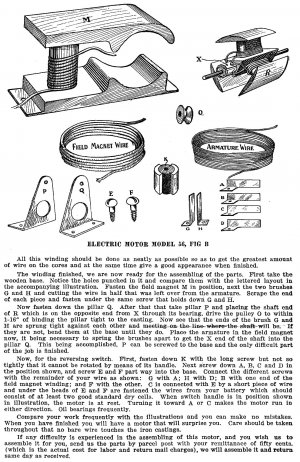

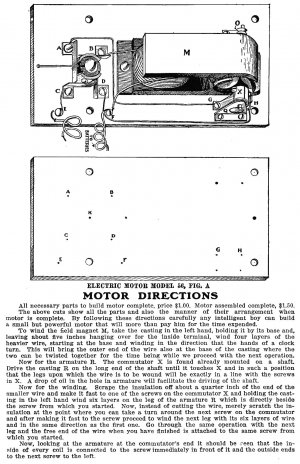

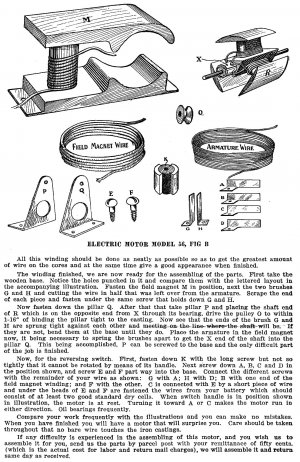

Here’s a snippet from the 1913 manual showing the construction of the motor.

The Gilbert company sold over 30 million Erector sets during their history. Why reproduce a motor? Turns out the 1913 motor is extremely scarce, there are less than 10 known to exist. The last original motor to show up on eBay surfaced in 2007 and sold for $3500! I threw one on eBay and here’s where it ended.

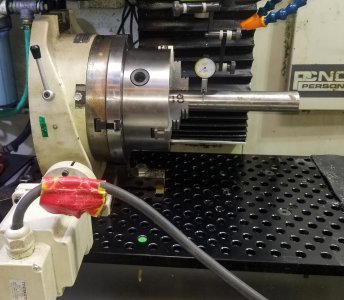

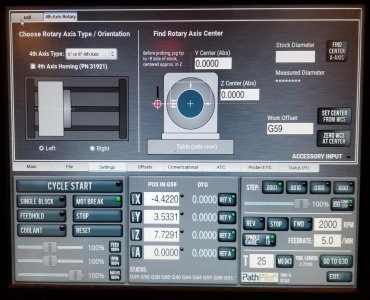

Naturally, a reproduction is not worth anywheres near an original. I took on the project more as a learning experience than anything. I bought a Tormach 1100 CNC mill in July, 2019 and made heavy use of it to make the parts that make up the motor assembly. I still haven’t learned any CAD/CAM packages (have access to both Solidworks and Unigraphics) and plug along with G-code. Fortunately, the parts in this motor are relatively simple to plot out with my Post drafting machine, programming was fairly easy.

If you look at most small DC motors, the field magnet and armature are generally made from stacks of steel plates. Lots simpler to stamp out a pattern and stack them for thickness. This motor had field core and armature made from solid iron castings.

I have lots of photos, so this will take a few posts. First part is the field core casting. I’m one of the lucky few to own an original motor. And “NO”, I didn’t pay $3500! I noticed what looked like the armature and field core castings in a non-descript pile of parts. I didn’t ask the seller for more photos which would potentially create some competition on the bidding. Instead, I took a chance and won it for $40. You can imagine my sh*t-eatin’ grin when the package arrived; Yup, won most of a 1913 motor! From there I measured/traced the part and made up a couple of drawings.

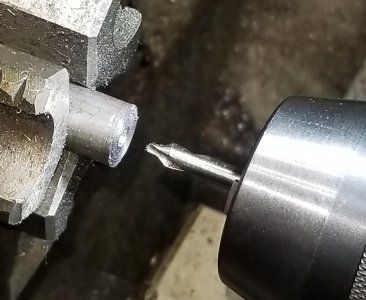

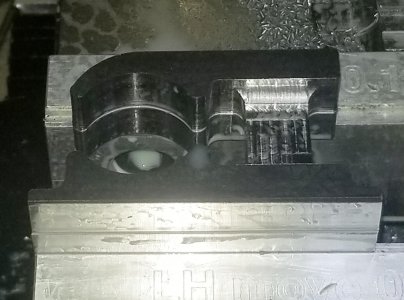

The original field core was made from cast iron. I went with A36 for the reproduction. The rough block is 2” x 4” x 1” thick. The original was also investment cast with probably a wax pattern. As a result, there was no parting line down the center of the part and no draft in the pattern as it wasn’t removed from the ceramic mold. I tried a couple of methods for making the part.

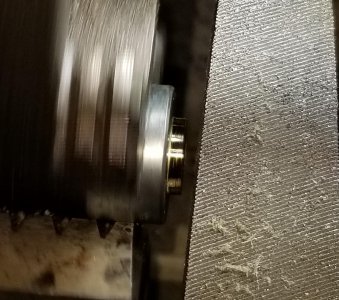

My first attempt was to run the pattern to 1.1” deep in a piece of A36 bar stock 2” x 4”. Then band saw off the part and clean up the opposite face to a 1” depth. I snapped a couple of ¼” deep end mills with DOC of around 0.080” on a full-width cut at a feed rate of 4 IPM. I wrote a pre-drill routine to knock in a series of ¼” holes so the end mill had some relief.

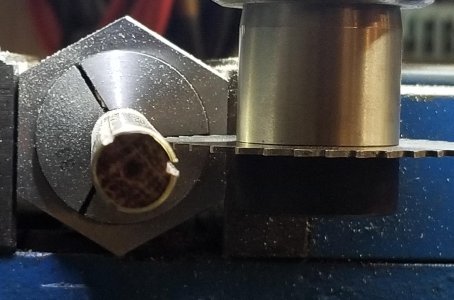

I ended up using either a ¼” rougher or ¼” 4-flute carbide end mill to a depth of 0.55”. Did one side, flipped the part and ran a mirrored routine to cut the opposite side.

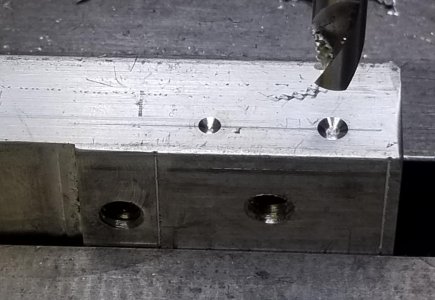

First side done

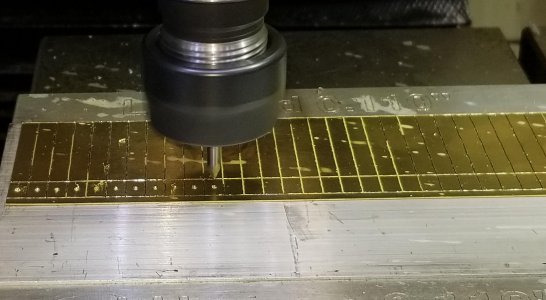

Flipped the part and aligned the edges using a passive probe and parallel

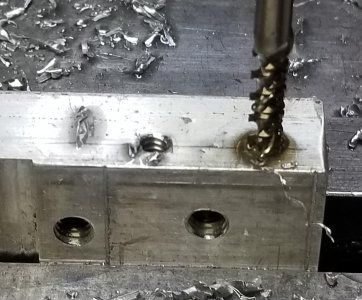

First op was drilling a hole for end mill clearance

Rough hog out the hole with a 3/8" roughing end mill

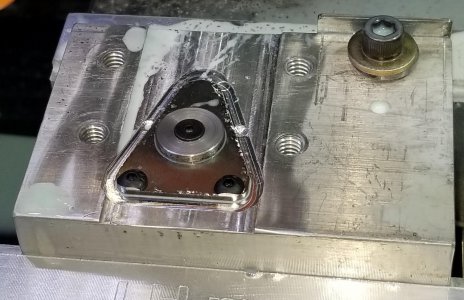

Routine complete on the back side.

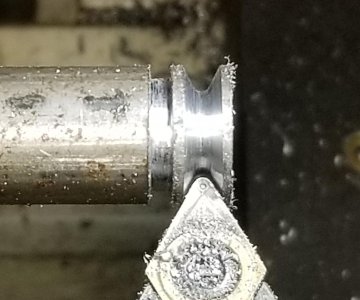

My alignment between cuts was not perfect, generally got within 0.005”. There was a little step where the opposite side routines met. The step was metal-finished with a 2” x 42” belt sander.

The original part was investment cast and had a stipple finish from post-casting sand or bead blasting. I tried simulating this with an impact hammer, but even at 15 psi was getting too deep of a dimple. I ended up going with a double-cut carbide burr in a Foredom grinder. It worked out pretty well, took me about 20 minutes to go over the part to add some radii on the edges and hit the flat surfaces for a simulated sand/bead blasted finish. Wish I had a bead blaster, that might have done a better job quicker.

Wore rubber gloves and a full helmet while doing the surface finishing. Lots of little slivers flying!

Finished part after grinding the surface. The burr did a pretty good job giving a cast-like appearance

Reproduction assembled 1913 Erector set motor

And it runs on 6V!

First, the obligatory history lesson. . . A.C. Gilbert introduced the Erector set in 1913. The sets came in various sizes numbering from No. 0 up through No. 8. Sets No. 4 – No. 8 included a “kit” to build an electric motor. The construction was a bit involved, so the factory offered to assemble the motor for $0.50 if the child sent the parts back to the New Haven factory.

Here’s a snippet from the 1913 manual showing the construction of the motor.

The Gilbert company sold over 30 million Erector sets during their history. Why reproduce a motor? Turns out the 1913 motor is extremely scarce, there are less than 10 known to exist. The last original motor to show up on eBay surfaced in 2007 and sold for $3500! I threw one on eBay and here’s where it ended.

Naturally, a reproduction is not worth anywheres near an original. I took on the project more as a learning experience than anything. I bought a Tormach 1100 CNC mill in July, 2019 and made heavy use of it to make the parts that make up the motor assembly. I still haven’t learned any CAD/CAM packages (have access to both Solidworks and Unigraphics) and plug along with G-code. Fortunately, the parts in this motor are relatively simple to plot out with my Post drafting machine, programming was fairly easy.

If you look at most small DC motors, the field magnet and armature are generally made from stacks of steel plates. Lots simpler to stamp out a pattern and stack them for thickness. This motor had field core and armature made from solid iron castings.

I have lots of photos, so this will take a few posts. First part is the field core casting. I’m one of the lucky few to own an original motor. And “NO”, I didn’t pay $3500! I noticed what looked like the armature and field core castings in a non-descript pile of parts. I didn’t ask the seller for more photos which would potentially create some competition on the bidding. Instead, I took a chance and won it for $40. You can imagine my sh*t-eatin’ grin when the package arrived; Yup, won most of a 1913 motor! From there I measured/traced the part and made up a couple of drawings.

The original field core was made from cast iron. I went with A36 for the reproduction. The rough block is 2” x 4” x 1” thick. The original was also investment cast with probably a wax pattern. As a result, there was no parting line down the center of the part and no draft in the pattern as it wasn’t removed from the ceramic mold. I tried a couple of methods for making the part.

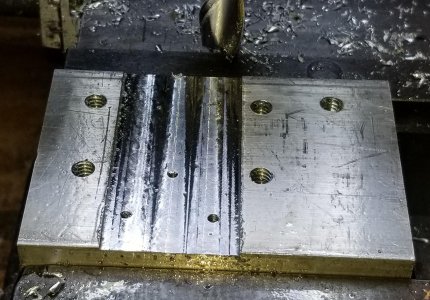

My first attempt was to run the pattern to 1.1” deep in a piece of A36 bar stock 2” x 4”. Then band saw off the part and clean up the opposite face to a 1” depth. I snapped a couple of ¼” deep end mills with DOC of around 0.080” on a full-width cut at a feed rate of 4 IPM. I wrote a pre-drill routine to knock in a series of ¼” holes so the end mill had some relief.

I ended up using either a ¼” rougher or ¼” 4-flute carbide end mill to a depth of 0.55”. Did one side, flipped the part and ran a mirrored routine to cut the opposite side.

First side done

Flipped the part and aligned the edges using a passive probe and parallel

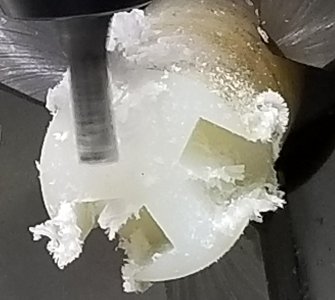

First op was drilling a hole for end mill clearance

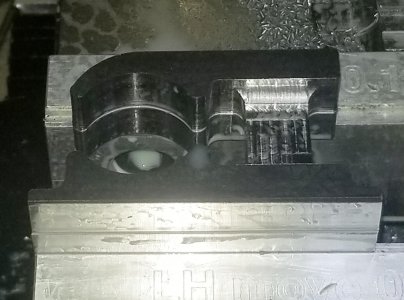

Rough hog out the hole with a 3/8" roughing end mill

Routine complete on the back side.

My alignment between cuts was not perfect, generally got within 0.005”. There was a little step where the opposite side routines met. The step was metal-finished with a 2” x 42” belt sander.

The original part was investment cast and had a stipple finish from post-casting sand or bead blasting. I tried simulating this with an impact hammer, but even at 15 psi was getting too deep of a dimple. I ended up going with a double-cut carbide burr in a Foredom grinder. It worked out pretty well, took me about 20 minutes to go over the part to add some radii on the edges and hit the flat surfaces for a simulated sand/bead blasted finish. Wish I had a bead blaster, that might have done a better job quicker.

Wore rubber gloves and a full helmet while doing the surface finishing. Lots of little slivers flying!

Finished part after grinding the surface. The burr did a pretty good job giving a cast-like appearance

Last edited: