- Joined

- Mar 26, 2018

- Messages

- 8,666

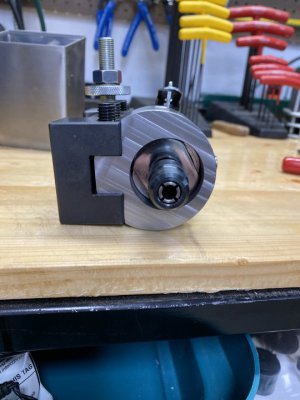

I saw something similar on Pinterist.

I used some scrap and put this together.

It’s rock solid in the holder. There are flats on the front of the air tool and I put a second 10mm 1.50 dog point. Much more robust than a Dremel.

The air tool has 27,000 RPM.

I just need to find some 1/4” arbor stones to test it out.

Total expense, $30. Much better than the >$500 alternatives.

I used some scrap and put this together.

It’s rock solid in the holder. There are flats on the front of the air tool and I put a second 10mm 1.50 dog point. Much more robust than a Dremel.

The air tool has 27,000 RPM.

I just need to find some 1/4” arbor stones to test it out.

Total expense, $30. Much better than the >$500 alternatives.

Attachments

-

34FA93CD-F975-4F50-9D1A-7B43662E9A5A.jpeg76.4 KB · Views: 84

34FA93CD-F975-4F50-9D1A-7B43662E9A5A.jpeg76.4 KB · Views: 84 -

7BC045D5-313E-43DE-8B97-AC66B2CB03F4.jpeg60.6 KB · Views: 76

7BC045D5-313E-43DE-8B97-AC66B2CB03F4.jpeg60.6 KB · Views: 76 -

BD38B50E-7FDF-4550-BA54-51F018AAA6D4.jpeg69.3 KB · Views: 76

BD38B50E-7FDF-4550-BA54-51F018AAA6D4.jpeg69.3 KB · Views: 76 -

90686180-77BD-439B-8514-6BFA529D4453.jpeg66.8 KB · Views: 78

90686180-77BD-439B-8514-6BFA529D4453.jpeg66.8 KB · Views: 78 -

F00809E1-C728-43DB-98F3-C642685C8976.jpeg79.6 KB · Views: 79

F00809E1-C728-43DB-98F3-C642685C8976.jpeg79.6 KB · Views: 79 -

B202B642-D2CC-4052-BAA6-A764EFD11FEC.jpeg81.3 KB · Views: 86

B202B642-D2CC-4052-BAA6-A764EFD11FEC.jpeg81.3 KB · Views: 86