- Joined

- Dec 27, 2014

- Messages

- 4,087

Those of us who have the smaller PM lathes, know what I'm going to discuss, the space takers for gear change setups.

Anyway.

When I first set up my shop, about 2014, I had found an unused Clausing “Atlas” lathe. It had the gear set with it, and I soon made a couple of banjos for changing gears from threading to feeding, and back.

Three years ago I advanced myself to a PM 1030 lathe, same problem, it took an hour to change from threading to feeds and/or back.

I had some 5/8” aluminum plate, to make banjos from, made three. I inlaid a piece of 3/16 steel to take the ends of the gear mount screws (so as not to chew up the aluminum).

I had found a trove of gears on Ebay at reasonable price. I was able to obtain a few of the sleeves with keys on them (for joining two gears on a shaft) from PM, and in was need of the spacers for when there's only one gear.

The problem with these spacers is that they have a keyway in them for the key on the sleeves (to tie the two gears together). I figured (wrongly) that I could file the keyway so they would work. I drilled a hole where the keyway would be two inches deep in a four inch piece of 4140 shaft, turned it to .820 OD and drilled and bored the hole to 14 mm to accept the sleeve. I cut off four spacers, 5/16 long.

I spent maybe an hour proving I couldn't file a keyway.

OK, how was the keyway done originally? It was broached. 5.1mm wide. Even if I had a 5.1mm broach, I couldn't use it on the four spacers I had started, the teeth would be farther apart than the spacers were long.

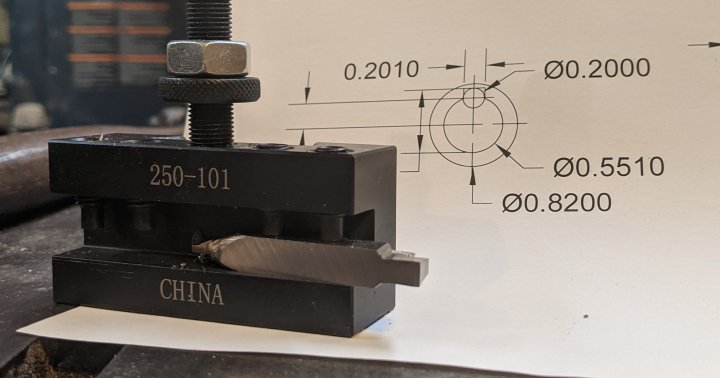

I wound up grinding a single broach tooth from a 5/16 HHS tool blank (should have used a .250, less grinding needed). I mounted it in an Aloris type tool holder and put a spacer in the three-jaw chuck. I turned the compound around so that .001 on the dial resulted in advancing the tool .0005, and very slowly broached the four keyways, pushing the saddle with the quill of the tailstock.

As my cut got deeper (half a drilled hole to be removed) I noticed that the tool wanted to pull itself into the cut. I had forgotten that each tooth on a broach had a tiny flat behind the cutting edge, parallel the motion of the broach to keep it from digging in.

I now have one banjo for feeds, one for each, metric and imperial threads, and one for whatever I need in a hurry. I'm still looking for more gears, though. Boston Gear will be a last-resort.

Anyway.

When I first set up my shop, about 2014, I had found an unused Clausing “Atlas” lathe. It had the gear set with it, and I soon made a couple of banjos for changing gears from threading to feeding, and back.

Three years ago I advanced myself to a PM 1030 lathe, same problem, it took an hour to change from threading to feeds and/or back.

I had some 5/8” aluminum plate, to make banjos from, made three. I inlaid a piece of 3/16 steel to take the ends of the gear mount screws (so as not to chew up the aluminum).

I had found a trove of gears on Ebay at reasonable price. I was able to obtain a few of the sleeves with keys on them (for joining two gears on a shaft) from PM, and in was need of the spacers for when there's only one gear.

The problem with these spacers is that they have a keyway in them for the key on the sleeves (to tie the two gears together). I figured (wrongly) that I could file the keyway so they would work. I drilled a hole where the keyway would be two inches deep in a four inch piece of 4140 shaft, turned it to .820 OD and drilled and bored the hole to 14 mm to accept the sleeve. I cut off four spacers, 5/16 long.

I spent maybe an hour proving I couldn't file a keyway.

OK, how was the keyway done originally? It was broached. 5.1mm wide. Even if I had a 5.1mm broach, I couldn't use it on the four spacers I had started, the teeth would be farther apart than the spacers were long.

I wound up grinding a single broach tooth from a 5/16 HHS tool blank (should have used a .250, less grinding needed). I mounted it in an Aloris type tool holder and put a spacer in the three-jaw chuck. I turned the compound around so that .001 on the dial resulted in advancing the tool .0005, and very slowly broached the four keyways, pushing the saddle with the quill of the tailstock.

As my cut got deeper (half a drilled hole to be removed) I noticed that the tool wanted to pull itself into the cut. I had forgotten that each tooth on a broach had a tiny flat behind the cutting edge, parallel the motion of the broach to keep it from digging in.

I now have one banjo for feeds, one for each, metric and imperial threads, and one for whatever I need in a hurry. I'm still looking for more gears, though. Boston Gear will be a last-resort.